T

ROUBLESHOOTING

There are no user repairable parts within the DF1000D. Attempting to repair the unit yourself

will only void the warranty. If you have a problem with your DF1000D, consult the following trou-

bleshooting guide. If this does not remedy your problem, please contact NMP at 888-667-2767

for assistance.

The DF1000D does not turn on.

1. Check the inline fuse located on the main power supply to the unit. If it is blown, replace it with a 1 amp, normal blow fuse. Clean all corrosion from

the fuse housing, and replace the fuse holder assembly if necessary.

2. Check the power cable connection. Be sure that the unit is connected to a known power source: RED wire to positive, BLACK wire to negative or

ground.

3. Ensure that the power source is powered using a test light, or some other reliable form of testing 12 volt power.

4. If you are sure that the unit is receiving power and is still not turning on, please refer to the warranty and service section.

The Bottom Reading is Random, Flashing, or Appears as

“---”

on the display.

1. The depth is less than 2.5 feet or greater than 200 feet. Operate the unit under normal operating specifications and check to see if it operating prop-

erly.

2. If this condition occurs only at certain speeds, then a transducer adjustment is needed. Refer to the “Helpful Hints for Transducer Installation” sec-

tion below. Refer to the Transducer Installation Instructions for adjustment procedures.

3. Under certain circumstances the DF1000D may not perform at the best of its ability. Extremely dirty water, very soft bottom, high speeds, deep

water, or a combination of the above will result in incomplete or inaccurate readings. Please refer to the Transducer Installation Instructions to min-

imize the effects of these conditions.

4. If the transducer is transom mounted check to make sure that the transducer is not “kicked-up”. To prevent damage to the transducer, it will auto-

matically release from the mounting bracket (kick-up) when it is impacted. If this occurs refer to the Transducer Installation Instructions to reset the

transducer for normal operation. If this happens frequently make sure that the trailer or boat lift supports do not interfere with the transducer during

loading and unloading.

5. Check the transducer cable connection on the back of the unit. Make sure that the connection is made as per the instructions in the Connecting the

Transducer section of this manual.

6. Contact NMP at 888-667-2767 for assistance if you are unable to correct the problem.

Helpful Hints for Transducer Installation (Transom Mounting)

1. Make sure the transducer is not mounted in any area where the water flow is interrupted by propeller turbulence or

aerated water. If standing at eye level, behind the transducer and looking forward along the bottom of the boat hull

there should NOT be any strakes, chimes, steps, or hull fittings inline with the transducer. If there are any of these

obstructions, the transducer will need to be relocated to achieve optimal performance. The transducer CAN NOT be

transom mounted on a Stepped-Hull vessel, it must only be in-hull mounted.

2. Make sure that the leading edge (bow - side closest to the bow of the boat) of the transducer extends at least 1/8” (3

mm) below the bottom of the hull. Also make sure that the trailing edge (stern - side furthest from the bow of the boat)

is 1/16” to 1/18” (1-3 mm) below the leading edge (Figure 11)

releasing the key will change the value in 1-foot increments per second. Holding down the key will change the value in 9 foot increments per second.

3. After your selection is made, the unit will return to normal operation after 5 seconds.

4. The " "and " " icons will now be present

When triggered, the alarm sounds an audible "alarm" for ten seconds while flashing the warning LED and the " "and “ “ icons on the display. After

10 seconds the audible alarm mutes and the warning LED and the " " and " " icons continue to blink until the depth increases, or the alarm is reset.

To reset the alarm repeat step 1 thru 4.

Setting the Keel Offset

The Keel Offset feature is used to adjust the depth readings displayed by the DF1000D to compensate for the depth of the water required for your ves-

sel to operate safely.

For Example:

If your boat’s draft is 3 feet, the Keel Offset feature should be set to 3 feet. The DF1000D will then sub-

tract 3 feet from the actual depth reading, and display this figure as the depth. If the water depth is 5 feet and the Keel

Offset is set to 3 feet, the depth will be displayed as 2 feet, indicating to the operator that there is 2 feet of safe operating

water.

The maximum Keel Offset setting is 20 FT (6.1 M), settable in .1 (1/10

th

) Foot or Meter increments. The DF1000D will read

“---” when a negative value occurs due to the Keel Offset Subtraction.

To set the KEEL OFFSET:

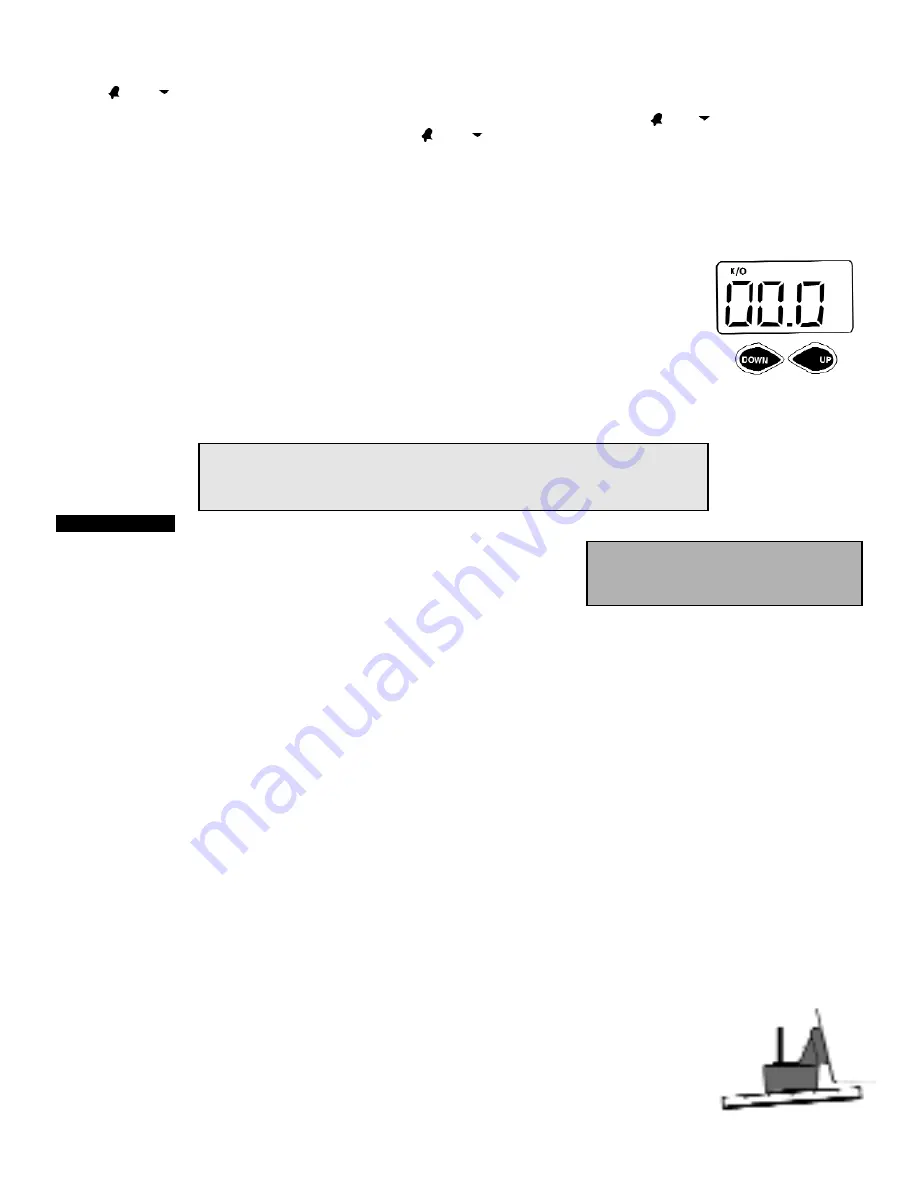

1. Press and hold the “UP” and “DOWN” keys at the same time for 3 seconds. When “K/O” begins flashing in the upper

left hand corner of the display, release the keys. (see figure 10)

. Press the "UP” key to increase the Keel Offset value. Press the "DOWN" key to reduce the value.

3. The display will return to the normal operation mode after five seconds if no keys are pressed.

4. “K/O” will remain illuminated in the top left hand corner indicating that the depth readings are adjusted to the Keel Offset setting.

WARNING!!!!

If you are unsure of the Draft of your vessel, please consult with the vessel’s manufacturer

before setting the Keel Offset. An improper Keel Offset setting can cause accidently ground-

ing of the vessel and may cause severe damage to the vessel and it’s passengers.

Figure 10

WARNING:

Disassembly of the electronic components

within this unit may result in exposure to lead in the form

of solder, which is known to the state of California to

cause cancer, birth defects, and other reproductive harm.

Figure 11

slight angle

- 3 -