MAINTENANCE

7

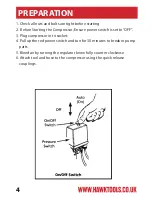

1. Do not carry out any maintenance whilst compressor is on - ensure

motor is not running, compressed air and condensation is bled and

compressor is disconnected from any power supply (see pages 5 + 6).

2. Pull ring on safety valve an allow it to snap back in to normal position.

Safety valve must be replaced if it cannot be actuated or it leaks air

after ring is released.

3. Turn compressor off and release pressure from system. Drain moisture

from tank by opening drain cock located on the underside of the tank.

4. Clean dust and dirt from the motor, tank, airlines, pump and cooling

fins while compressor is off.

5. Unclip the air filter cover, remove the filter and blow away any loose

dirt. If damaged or badly contaminated, it must be replaced.

6. Clean the fins of the compressor cylinder and the cylinder head to

receiver pipe.

7. Locate the compressor as far away from spraying area as possible,

Extending the hose will help prevent overspray which may clog the

filter. Take care not to over extend.

8. Do not lubricate. Oil-Less compressors require no lubrication.