Hateflex spiral hose

EN

14

Art. Nr.: 5090031096 Rev.: 02/2021-10-14

4

Distance (A)

5

Ø d

outside

Safety duct

6

Ground trench: stone-

less, with 10 cm compacted

sand bed

7

Height pipe bond

8

10 cm: limitation above the embedment according

to DIN EN 1610

9

Coverage

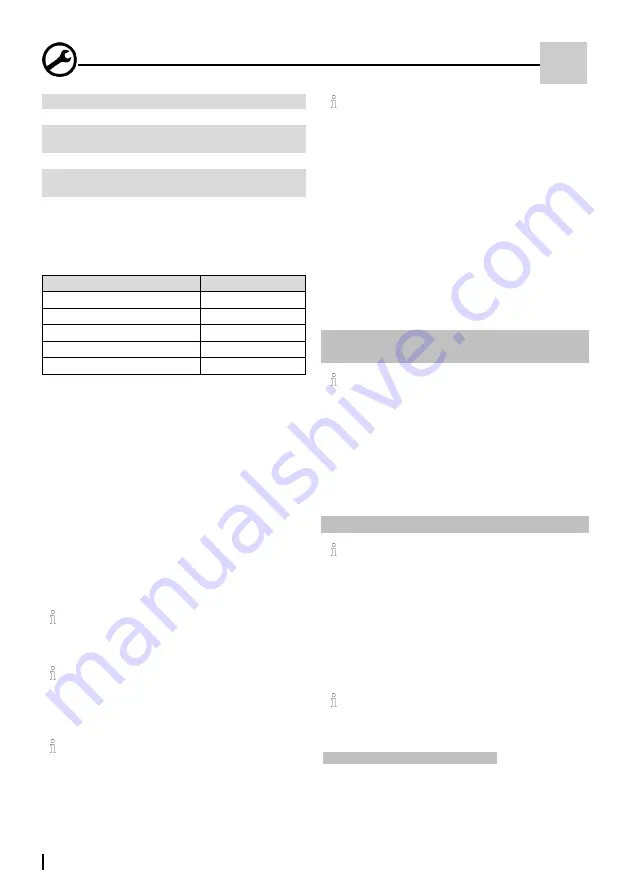

Based on the ducts outer diameter, consider the following

distances: (see Table 1).

Table 1

Hauff-spiral hose Ø d

outside

Distance (A)

87 mm (Hateflex 14078)

min. 30 mm

102 mm (Hateflex 14090)

min. 30 mm

125 mm (Hateflex 14110)

min. 40 mm

140 mm (Hateflex 14125)

min. 40 mm

168 mm (Hateflex 14150)

min. 40 mm

5

If more than two hoses are laid, the spacers must be

plugged together.

The eyelet must be placed on the spigot (see fig.: 3

and 4).

6

In the first layer, place the spacers directly on the

soil

and clip in the hose.

7

Backfilling of the space around and between the

pipes.

8

In the case of multi-

layer hose systems, the spacers

are placed on the respective hose layer below. The

hoses can now be clipped in place (see fig.: 2).

9

Go on with the follo

wing layers in a similar way.

To avoid a damage of the pipes and seal inserts

of the cable entry systems (HSI90 and HSI150),

use only slightly compacting machines for com-

pacting of the filling material

Please note the following rules therefore:

•

Technical guideline ZTVE-StB 94/97 (19) and

ZTVE-StB 97 (18)

•

DIN norms about classification of grounds

The usage of middle and heavy stamping or

vibrating machines in part of the summit

covering (measured in compacted status) is not

allowed under 1 m!

Following factors show the possible transfer

lengths:

•

Cable (type/ weight/ flexibility)

•

Cable run (height)

•

Quantity/ position/radius of curves/inaccuracy

•

Coefficient of friction (cable/pipe wall)

•

Lubricant (type/ quantity)

•

Method and speed of the move-in ( incl.

surface temperature)

•

Proportion pipe ID/cable OD

•

Quality of the installation, for example:

Pipe support/ compaction of the embedment

material = influence onto pipe deforming,

Backfilling/ compaction of the embedment

around pipe bows/ curves = important for ab-

sorption of mechanical load while cable entry.

6

Connection of the Hateflex hose system

onto chambers and stations

For the connection of the Hateflex hose systems

onto chambers and stations, you can use the

Hauff Cable Entry System (HSI90/HSI150). HSI

Cable Entry Systems need to placed in formwork

before concreting.

For the pipe connection system for all pipe di-

mensions of the Hatefles hose system, you can

use pipe connection sleeves made from rubber.

The cable entry system is not able to absorb

weight/ pressure of the cable safety duct.

7

Bending radiuses

The minimum bending radiuses of the duct ma-

nufacturers must be observed.

The following minimum radiuses apply to Hauff

-Technik

Hateflex systems at an

installation temperature of 20 °C:

Hateflex14078: 400 mm

Hateflex14090: 400 mm

Hateflex14110: 500 mm

Hateflex14125: 600 mm

Hateflex14150: 900 mm

However, the minimum bending radiuses of the

media lines/cables to be installed must be obser-

ved.

Service tel 49 7322 1333-0

Subject to change!