48

1019658 11/2014

5.9.1 Assembly of the Circular Spline

The Circular Spline must not be bended during the assembly. Therefore it is particularly important that the mounting base

of the Circular Splineis absolutely even and that the mounting base centering causes neither clamping strength nor radial

clearance.

Explanation:

A slightly deformed Circular Spline can result in irregular running characteristics. If a deformation of the Circular Spline is

suspected it should be verified whether the Circular Spline can rotate freely within its locating bore in the machine housing

without any friction. Even slight friction may be an indicator for a possible radial deformation of the Circular Spline. In this

case the tolerances of the machine housing and the Circular Spline must be checked.

For grease lubrication the Circular Spline teeth must be lubricated in accordance with illustration 43.1. For the correct

mounting please also see illustration 39.1.

Circular Spline Screws

Table 48.1

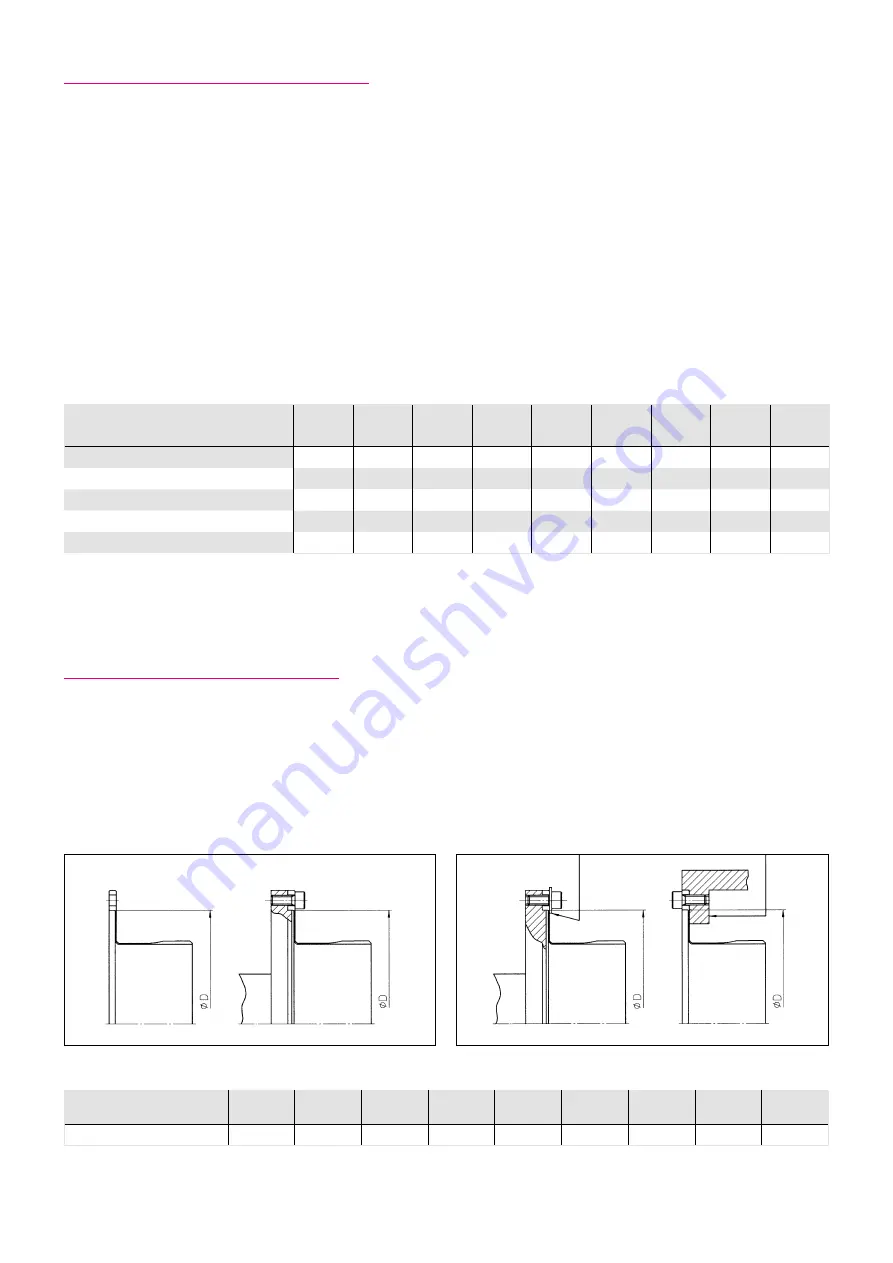

5.9.2 Assembly of the Flexspline

Care must be taken that the heads of clamping bolts, washers, nuts or clamping rings do not interfere with local flexing of

the Flexspline. Otherwise eventual failure will result.

For this reason, fastening elements must not enter the region which is marked by ø D. Please refer to illustration 48.2.

Illustration 48.2

Illustration 48.3

Size

14

17

20

25

32

40

45

50

58

Number of screws

6

12

12

12

12

12

12

12

12

Size of screws

M3

M3

M3

M4

M5

M6

M8

M8

M10

Pitch circle diameter [mm]

44

54

62

75

100

120

140

150

175

Clamping torque [Nm]

2.0

2.0

2.0

4.5

9.0

15.3

37

37

74

Torque transmitting capacity [Nm]

54

131

147

314

675

1150

2440

2620

4820

Right

Wrong

Table 48.4

[mm]

Size

14

17

20

25

32

40

45

50

58

ø D

48

60

70

88

114

140

158

175

203

The tables are valid for completely degreased pads (friction coefficient µk = 0.15) and metric socket head cap screws according to EN ISO 4762 in 12.9 quality,

untreated, oiled, with µtotal = 0.12.