8

3-90-07205R26_10/14

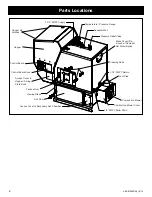

Refer to the illustration under

“Parts Locations”

in this

manual to identify the components listed below:

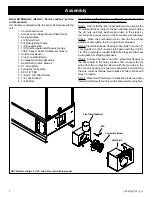

1. Install the control board cover as well as the access cover

located on the feeder cover.

2. Install the spring handles provided with the unit on

the ash door, firebox door and the heat exchanger

cleanout rod handles. (Fasten handles by turning them

counterclockwise and pushing inward simultaneously).

3. Install 3/4” MPT boiler drain in the fitting as shown.

Note: Use pipe thread sealant or Teflon tape on ALL

threads before connections are made.

4. Install 3/4” MPT pressure relief valve as shown.

5. Install the 1/2” MPT aquastat well in fitting as shown, then

place aquastat in the well and fasten with a zip tie. The

aquastat sensor is located under the top sheet metal

jacket.

6. Install the 1/2” MPT temperature/pressure gauge in fitting

as shown.

7. Locate and install outside air temperature sensor. Location

of this sensor should be on the north side of the home or

building and out of direct sunlight. Use the cable supplied

with the boiler to attach the sensor to the terminals located

on the hopper. (Place at the back side just above and to

the right of the main power connection box) The wires can

be connected to the sensor with the connectors supplied.

Wire nut or butt splice connectors could also be used. The

connections at the boiler can be done with the two 1/4”

female push on connectors supplied.

8. Fasten the conduit to the ash base with the clamps

provided.

design:

The first thing that needs to be done is deciding where and

how the boiler will be installed.

Things that need to be taken into consideration are the

intended use of the boiler for example, is the boiler going to be

used as your primary heating system or is it going to be used

as a secondary or backup heating system. If it is to be used

in conjunction with an existing oil or gas boiler system will it

be piped in parallel or in series? The answers to these and

other questions can be determined by talking to your certified

dealer or a qualified HVAC or plumbing contractor. This will

ensure that the boiler is installed and piped to accommodate

your needs and expectations.

Consideration must be given to the venting as well as

electrical and clearance requirements. (Clearances must be

maintained to combustibles and also for service)

Make sure fans are not used in the fuel storage area, unless

they are installed so as not to create a negative pressure in

the room where the solid fuel burning appliance is located.

Assembly

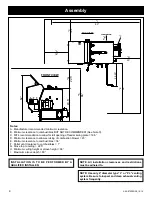

Floor Protection:

The striped area indicates the minimum required floor

protection area if the boiler is going to be placed on a

combustible floor. It requires 40” X 55”(US) or 42” X 55”(CAN)

of non combustible floor protection as shown. 16”(US) or

18”(CAN) of the floor protection must be in front of the firebox

door as shown. Floor protection must be a minimum of 26

gauge sheet metal. Floor protection must also be provided

under any horizontal run of vent pipe equal to the outside

diameter of the venting plus 2” to each side.

example:

4” type “L” or “PL” vent pipe has an outside

diameter of 4-1/2” + 2” on each side equals a protected floor

area of 8-1/2” wide underneath the horizontal run.

42" C

ANADA

18" C

AN

16" USA

40" USA

55" USA & CAN

MINIMUM NON-COMBUSTIBLE FLOOR PROTECTION AREA

NON-COMBUSTIBLE

FLOOR PROTECTOR

55" USA & CAN

42" C

ANADA

40" USA