6

Riggers Winch 200

01/03/19

Installation

A. PLAN INSTALLATION

The adapter plate can be affixed in a number of ways dependant on the environment and industry; these

include ratchet straps, fibre slings and strops and karabiners, making for a truly universal and adaptable lifting

solution.

It is the installer’s responsibility to carry out all structural tests needed to ensure that the mounting surface

can withstand the load.

Lifting Rope - Entry Angle

The winch plate must be installed so that the line can be led through the rope guide to the winch drum, with

no more than 30

o

of line deflection in any plane. The installation should use pulley deflectors if necessary to

ensure a fair lead to the winch. The rope guide should not take any significant angle load. (See diagram)

Mounting Plate - Attachment

Ensure the plate is securely attached to the mounting surface, so that it can operate under load without

significant movement.

The following illustrate some possible ways that the plate can be mounted.

Riggers Winch 200 - Location

The Winch kit must be installed in a position to allow sufficient working space around the unit, so not to

impede operation of the handle.

The stripper arm must be in a 4 o’clock position once the plate is mounted.

The Winch kit must be installed in a position to ensure visibility of the lift trajectory by the operator at all times.

The following illustrate some possible ways that the plate can be mounted.

WARNING!

Leading the rope directly on to the drum can cause overrides and damage winch or make winch

inoperable, leading to loss of control, possibly resulting in severe injury or death. Always lead the rope

through the rope guide

30

o

max. deflection

30

o

max. deflection

Содержание Riggers Winch 200

Страница 2: ...2 Riggers Winch 200 01 03 19...

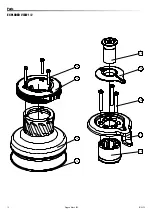

Страница 18: ...18 Riggers Winch 200 01 03 19 Parts EXPLODED VIEW 1 2 14 13 15 16 12 17 18 19 20...

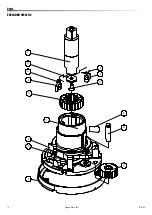

Страница 19: ...19 Riggers Winch 200 01 03 19 Parts EXPLODED VIEW 2 2 2 1 4 5 11 4 5 7 3 6 10 9 8 4 5...

Страница 22: ...22 Riggers Winch 200 01 03 19...

Страница 23: ...23 Riggers Winch 200 01 03 19...