GB 14 02 02 MA

Maintenance

R

R

R

R

Re

ee

e

epair of

pair of

pair of

pair of

pair of the ba

the ba

the ba

the ba

the bag

g

g

g

g

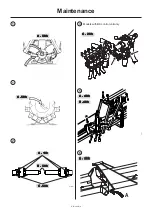

If the air bag is damaged it can be repaired by sewing or

gluing a patch on it. A repair kit is available; HARDI ref.

no. 728746.

Oil cooler

Oil cooler

Oil cooler

Oil cooler

Oil cooler

The cooler under the fan must be inspected externally at

least yearly and cleaned if necessary. Remove the bag

and check that the cooler ribs are clean. A pressure

cleaner can be used to clean the ribs. When the bag is

replaced, unfold the boom to check it is centred and

angle the air outlet forward to check there is no slack in

the bag.

Hy

Hy

Hy

Hy

Hydr

dr

dr

dr

draulic tr

aulic tr

aulic tr

aulic tr

aulic transmission

ansmission

ansmission

ansmission

ansmission

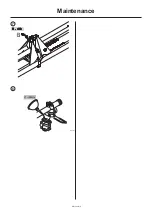

If the hydraulic motor has been dismantled or replaced,

the following start-up procedure has to be done:

1. The boom needs

to be unfolded so

choose a location

where this is possible.

2. Remove the snap

coupler from hy. motor the

drain line and place the

hose in a small

container. Set the

valve for blower fan

revolutions at or

near minimum and with the

tractor engine at idle, unfold the

boom.

3. Adjust valve

A

for blower fan

revolutions so the fan rotates between

300 to 500 r/min for 5 minutes or until oil

comes from the drain line. The sprayer

hydraulics are now filled with oil and the

valve can be set to maximum and tractor r/min in-

creased to check for possible leakage.

4. Check oil pressure filter (if fitted) indicates green (not

clogged).

5. Replace the drain line snap coupler. Check the tractor

hydraulic oil level and top up if needed.