Page 18

For technical questions, please call 1-888-380-0318.

Item 63793

S

AFET

y

M

AINTENAN

c

E

B

ASI

c W

EL

d

IN

g

W

EL

d

IN

g T

Ip

S

SETUP

Troubleshooting

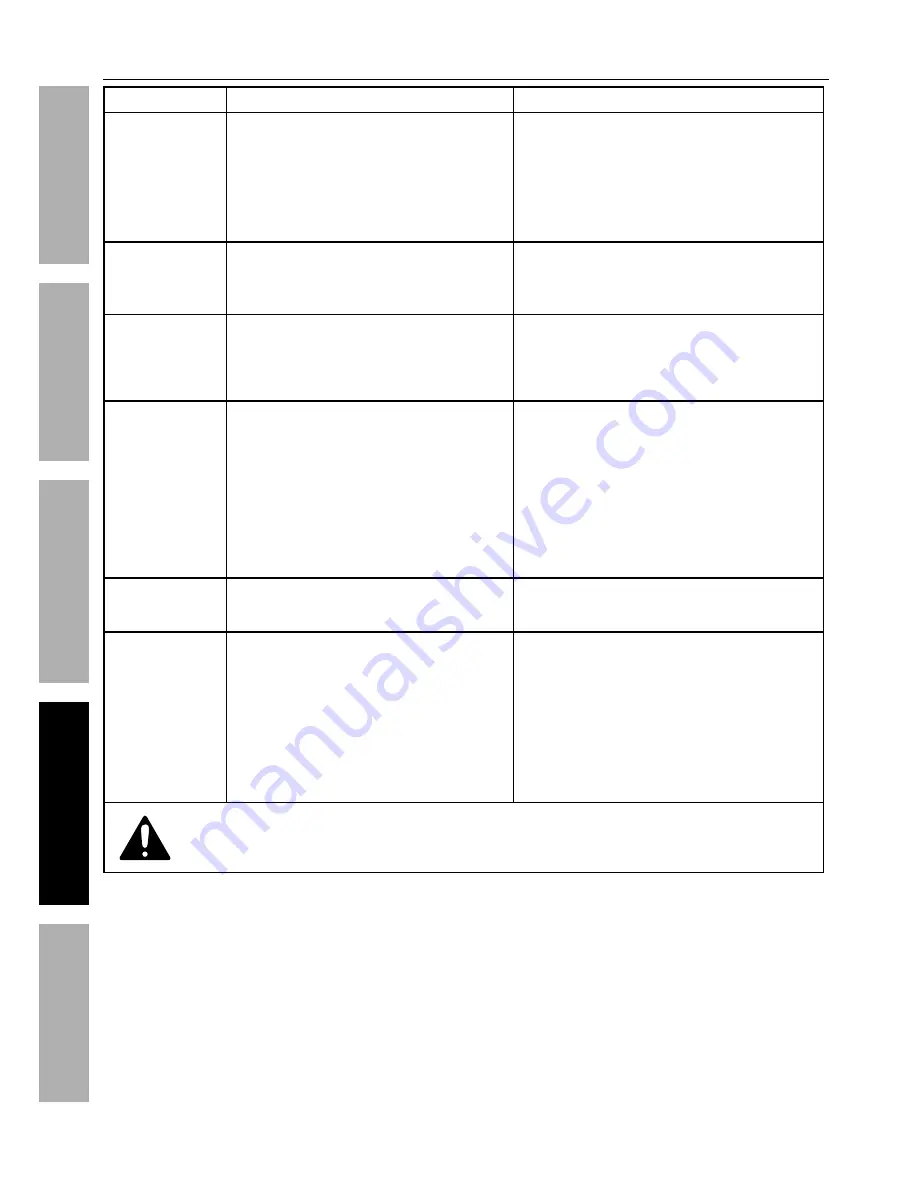

problem

possible causes

Likely Solutions

Wire feed motor

runs but wire does

not feed properly

1. Tension Knob is too tight.

2. Damaged Gun, cable, or liner assembly.

3. Tension Knob is too tight.

1. Tighten Tension Knob so it applies only

enough pressure to prevent continued

spinning after the Gun Trigger is released.

2. Have a qualified technician inspect these

parts and replace as necessary.

3. Loosen Tension Knob so it applies only

enough pressure to prevent continued

spinning after the Gun Trigger is released.

Wire creates a bird’s

nest during operation

1. Tension Knob is too tight.

2. Incorrect Contact Tip size.

3. Damaged liner.

1. Loosen Tension Knob

2. Replace with the proper tip for wire used.

3. Have a qualified technician inspect

and repair/replace as necessary.

Wire stops

during welding

1. Gun liner is clogged or worn.

2. Wire is tangled on the spool.

3. Tension Roller is not making

enough contact with wire.

1. Check gun liner for obstruction, blow out with

compressed air. Have liner replaced if necessary.

2. Check wire for cross winding or tangled spool.

3. Check Tension Knob and ensure it is set properly.

Wire feeds, but arc

does not ignite

1. Improper ground connection.

2. Improperly sized Contact Tip.

3. Excessively worn Contact Tip.

4. Dirty Contact Tip.

1. Make certain that the workpiece is contacted

properly by the Ground Clamp and that

the workpiece is properly cleaned near the

ground clamp and the welding location.

2. Verify that Contact Tip is the proper size

for welding wire. If needed, replace

Contact Tip with proper size and type.

3. Check that the hole in the tip is not

deformed or enlarged. If needed, replace

Contact Tip with proper size and type.

4. Properly clean Contact Tip.

Porosity in the

weld metal

1. Gun is being used too far away from workpiece.

2. Dirty welding wire is introducing

contamination into the weld.

1. Check CTWD (contact tip to work distance).

2. Make certain that welding wire is clean

and free of rust and residues.

Welding arc

not stable

1. Wire not feeding properly.

2. Incorrect or damaged Contact Tip.

3. Loose Gun cable or ground cable.

4. Damaged Gun or loose connection within Gun.

5. Gas coverage may be insufficient or too high.

6. Poor connection with workpiece.

1. See first Troubleshooting section above.

2. Replace Contact Tip.

3. Check to ensure that all connections are tight.

4. Have a qualified technician inspect

and repair/replace as necessary.

5. Ensure gas flow rate is set according to Settings Chart.

Make sure Gun Cable Connector is fully inserted into

Wire Feed mechanism with no O-Rings exposed.

6. Check the ground clamp connection to the workpiece

and machine. Ensure the Gun is properly secured.

Follow all safety precautions whenever diagnosing or servicing the equipment.