16

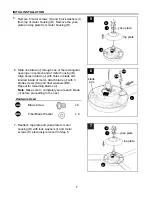

2. Restore electrical power. Within 30 seconds of

restoring electrical power, press and hold the “0”

button on the remote control transmitter for 5 seconds

or until light on the fan blinks twice. Use the remote

control transmitter to test the light and fan functions to

confirm the learning process is complete.

NOTE:

Remove protective covering from front of

remote control transmitter and discard.

IMPORTANT:

To prevent damage to remote control

transmitter, remove the battery if not used for long

periods. Store the remote control transmitter away

from excess heat or humidity.

2

Remote Control Transmitter

OPERATING INSTRUCTIONS

Operation buttons on the panel of the remote control

transmitter:

3

button

for fan

HIGH

speed

2

button

for fan

MEDIUM

speed

1

button

for fan

LOW

speed

0

button

to turn fan

OFF

button

to turn light

ON

or

OFF

Tap button quickly to turn lights off or on. Hold

button down to increase or decrease lights. If you

press button in excess of 0.7 seconds, it

becomes a dimmer. The lights vary cyclically in

8 seconds. The light button has an auto resume

function, which keeps the light at the same

brightness as the last time it was turned off.

NOTE

: Most CFLs are NOT compatible for use with

dimmer controls.

3.

3

Remote Control Transmitter

4. Use the fan reverse switch on the switch housing to

optimize the fan for seasonal performance. A ceiling

fan will allow you to raise your thermostat setting in

summer and lower your thermostat setting in winter

without feeling a difference in your comfort.

CAUTION:

Turn fan off at wall switch and let

blades (J) come to a complete stop before manually

activating the reverse switch.

4

reverse switch

motor housing