8

A100b

JAN 2009

SETTING ADJUSTMENTS OF SENSORS

There are several selectable features included in the

Hansen Gas Sensor. Refer to pages 6 and 7 for the

adjustable features. Note the adjustment screws on

the circuit board for the electrochemical sensor have

a different layout then the semiconductor sensor. The

jumpers may be moved without shutting off the power.

With the use of a 12-24V AC/DC power source, these

sensors can be set to the customers specifications

prior to mounting the gas sensor in the engine room or

refrigerated area.

Relay and Horn Set Point

The adjustment screw A sets the trip point for the relay

and the alarm horn. A 0-5V scale measures the full sensing

range of the Gas Sensor. The trip point voltage can be

measured at points ØV and REF1 located on the board.

Refer to pages 6 and 7 for location of the reference pin

REF1. A 100 PPM range gas sensor reading 2.5 volts at

the reference pin would be equivalent to half the range

or 50 PPM.

Default factor y setting is 50% of range.

Note that the set point of the relay is independent

of the set points to the Gas Detection Monitor.

To

assist in selecting the correct voltage for the desired

PPM set point, refer to

Table 1

below.

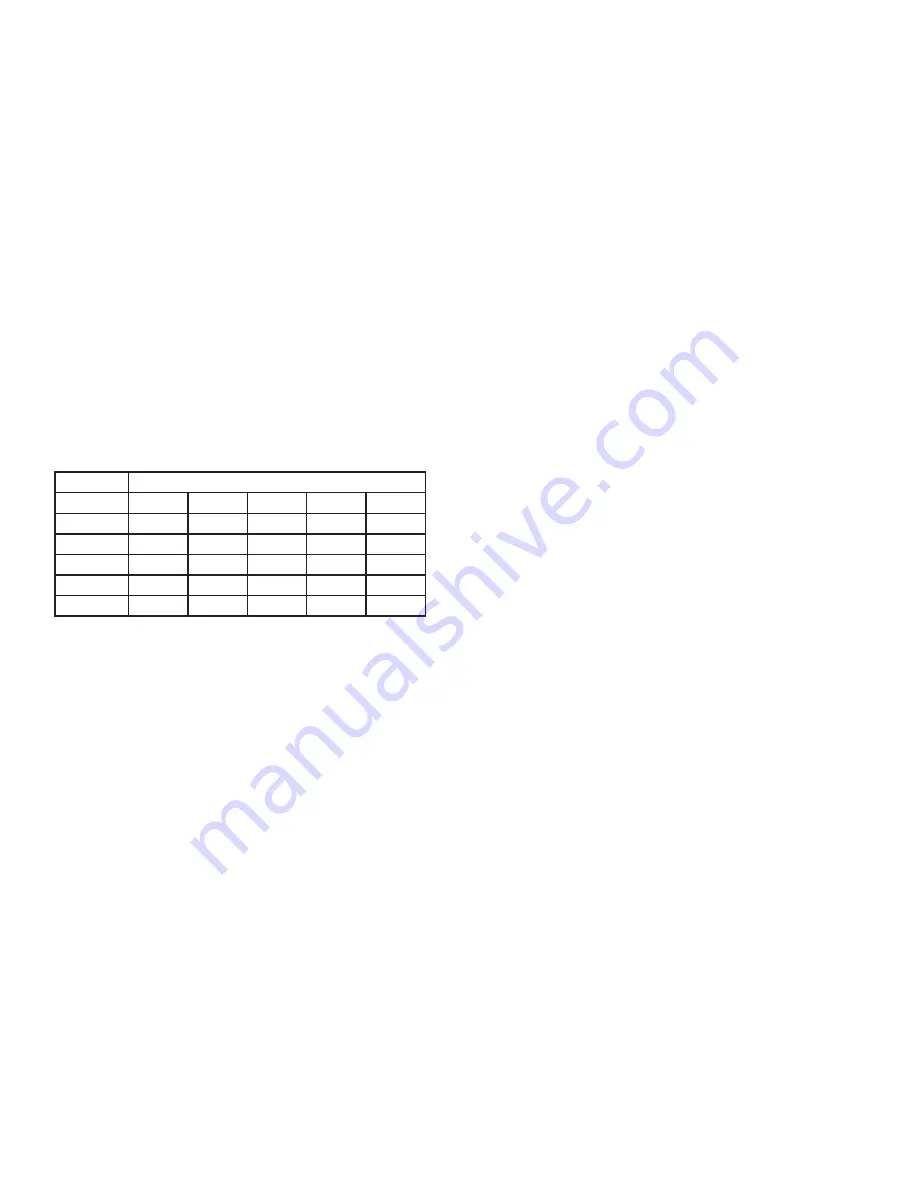

VOLTAGE

PPM R ANGE

5

100

250

500

3000

10,000

4

80

200

400

2400

8000

3

60

150

300

1800

6000

2

40

100

200

1200

4000

1

20

50

100

600

2000

.5

10

25

50

300

1000

TABLE 1

Setting Minimum or Maximum Relay Set Point

There is a practical limit for setting the minimum or

maximum relay set point. There is the tolerance of the

electronic board and the test meter. It is recommended

to keep the relay set point between 10% and 95% of

the range.

Time Delay

A time delay for the operation of the relay and alarm horn

can be selected using jumpers JP5 and JP6.

Default

factor y setting is zero.

Alarm Horn

Alarm horn is 40dB at 2 feet for Basic Sensor; all other

models not audible with cover closed. The alarm horn

can be disabled using jumper JP2.

Default factor y

setting is enabled.

Adjustment of the Detection Range

Adjustment Screw Z sets the zero (0 PPM) and Adjustment

Screw S sets the span. (full range = 1000PPM, for

instance). The output of the sensor circuit can be

monitored via test points ØV and VS. The full range

equals 5 volts DC. See

Calibration Procedures

for

fur ther details.

GAS SENSOR OPERATION

On power up the internal relay will energize switching

from the normally closed position to the normally open

position. In addition, the sensor will go through an

initial warm-up delay for five minutes. At this time, the

I and V outputs are 0. This is indicated by the green

LED flashing approximately ever y second. After five

minutes, the green LED stays on continuously, indicating

power to the gas sensor and ready for service. The gas

sensor also sends a milliamp output signal to the gas

detection monitor, PLC, or computer. This output signal

is propor tional to the amount of the specific gas being

monitored in the air around the gas sensor. If signal

reads 0.5mA, it is an indication the sensing element has

failed or disconnected. Verify proper installation and

refer to testing and calibration procedures.

Fail Safe Operation

Hansen Gas Sensors feature a one amp SPDT alarm

relay for fail safe operation. In the event of a sensor

element failure, power loss or gas leak detection, the

internal relay will be de-energized. This relay can be

used to trigger an external alarm.

Start Up Test

Once the installation of the gas sensors and monitors

is complete, the entire gas sensor system should be

tested. Normally, two people are required—one person

using a small amount of the target gas to “bump” each

sensor in turn, a second person at the monitor location

to verify the sensor is connected to the correct input,

responds to the target gas and causes the lights and

alarms to respond.

Gas Sensor Testing

Field testing of the gas sensor is normally done for three

reasons. The first is to determine if the gas sensor is

responding to the specific gas. This test is sometimes

called a “bump” test. The frequency of the test is usually

stated in the facilities Process Safety Management (PSM)

document, but not less than ever y six months.

The second reason for gas sensor testing is to be sure

the gas sensor is properly calibrated. Depending on the

sensing element type, the sensor sensitivity will change

with time. In par ticular, electrochemical sensors use a

material that is depleted with time. The length of time

varies depending on the amount of exposure to the target

gas, the ambient temperature and humidity, and changes

to temperature and humidity range. Atmospheres that

are ver y dr y or ver y humid will shor ten the life of a

sensing element.

The third reason is to be sure the gas sensor output

triggers the alarms on the monitor, PLC, Gas Alert System,

horn or lights. Gas sensors should be recalibrated at

least once a year or sooner where the gas sensor is

frequently exposed to low concentrations of the target

gas. Semiconductor and infrared sensors should be

checked annually. All sensor types should be recalibrated

immediately after exposure to a large concentration of

the target gas.

Note: Insurance companies, local and state agencies

may require more frequent testing and calibration;

refer to insurance carrier mandates as well as local

and state codes.

Calibration of Electrochemical Sensors

Read the calibration instructions completely before

proceeding. If in doubt about a procedure, please

contact Hansen Technologies for fur ther assistance.