Hansa C27EU O&M Manual

– OM-023 Revision A 16/10/19

© Hansa Chippers 2019

14

Anvil adjustment

Whenever the chipper knives are inspected/sharpened, the condition of the anvil should also be checked. If the edge of the anvil

is significantly rounded and/or uneven, then it should be reversed or replaced. Typically the anvil will maintain its flat edge for

about 500 hours of operation.

Anvil replacement

Remove the feed roller guard by unhooking the

four rubber latches. Unhook the springs from the

base of the chassis. Lift the swing arm up and

insert the rotor pin (located underneath the

control panel) into the tab on the housing to lock

the swing arm in place (as per the diagram

below).

To remove the anvil, you must remove the three

countersink clamping bolts using a 16 mm socket

and extension. If the bolt head turns, hold it with

an 8 mm Allen key.

Note

:

Do NOT

use the Allen key to turn the bolt;

turn only the nut.

Note

: Ensure the gap between the knife holding

block and the edge of the anvil is 4 - 5 mm. If not,

then the anvil can be adjusted via the two

adjustment bolts between the clamping bolts.

If the other side of the anvil hasn’t been used yet: rotate the anvil 180 degrees and place it back on the

feed

roller housing wall. If both sides of the anvil are blunt: remove the anvil and replace it with a new one. Contact

Hansa if a replacement anvil is required.

Tighten the clamping bolts back up using a 16 mm spanner/socket, ensuring there is a spring washer between

the clamping plate and each nut. Torque the bolts to 44 Nm.

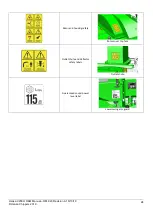

Belt tension

Correct belt tension is crucial for minimising belt wear and maximising machine efficiency. To check the belt tension, the belt guard

must first be removed (see step 1 of

‘Belt replacement’

on page 16). After the belt guard is removed, fully engage the belt. There

should be approximately 5 mm deflection in the belt when pressing firmly on the belt (as per the image below). If required, adjust

belt tension.

1

2

3

4

Countersink

clamping bolts

Rotor

locking pin

Feed roller motor

Swing arm

Check for

deflection

here