53

hours service of the brake and it is suggested to adjust the air gap every 6 months. If it comes to a

poor working condition, such as frequent use of brake and repeated emergency stops the air gap

should be set when the brake the shorten the adjustment interval for the first time.

1.5.5 Common fault and troubleshooting

Fault

Probable cause

Corrective action

Brake does not

work

Power is obstructed

Connect

Too low exciting voltage

Check voltage and adjust.

Improper air gap

Adjust air gap

Stator coil breaks

Replace stator

Oil dirt mixed in

Clean oil dirt

Long brake time

Switch installed to AC circuit

Install the switch to the DC circuit

after rectifying

Improper air gap

Adjust air gap

Oil dirt mixed in

Clean oil dirt

Slipping

Unstable operation in previous use

Breaking-in for a while

Oil dirt mixed in

Clean oil dirt

Large load

Reduce load or replace large

specification

Large load change

Adjust load peak or large the

specification

High temperature

Too high exciting voltage

Check voltage and adjust.

Clutch or motor interfere to the brake

Check control circuit, eliminate

interference

High environment temperature

Set ventilation

High operating frequency

Adjust to proper frequency

Over large load

Reduce load

Large noise

Product service environment needs

silence

Silence design

Impurity mixed in.

Clear away the impurity

Bad mounting

Replace mounting surface or shaft

Large rotational inertia or dynamic

unbalance value

Reduce rotational inertia or

dynamic unbalance value.

Содержание Mini Series

Страница 24: ...20 Fuse LED2 charging status indicator LED1 power indicator ...

Страница 45: ...41 ...

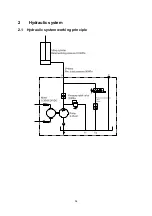

Страница 58: ...54 2 Hydraulic system 2 1 Hydraulic system working principle ...

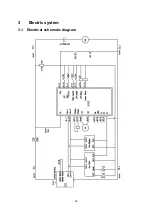

Страница 60: ...56 3 Electric system 3 1 Electrical schematic diagram ...

Страница 65: ...Maintenance Record Date Repair maintenance content Serviceman ...