2

Safety Instructions

Before using your Handler products, please read

safety instructions. They are for your protection and

should always be followed to reduce the risk of

personal injury or damage to the unit.

• Always wear proper eye and face protection.

Wear safety glasses or face shields whenever

you operate a Handler product or any power tool

to prevent serious eye or face injuries.

• Always disconnect the power cord before

removing or replacing the filter, servicing the unit

or when not in use.

• Always wear a face or dust mask to prevent the

inhalation of dust particles, or other debris into the

lungs.

• Keep the work area clean. Cluttered areas and

benches invite accidents.

• Don’t abuse the cord. Never carry tool by cord or

yank it to disconnect from receptacle. Keep cord

from heat, oil, and sharp edges.

• Secure the work piece. Use clamps or a vise

to hold work. It’s safer than using your hand and it

frees both hands to operate tool.

• Don’t Overreach. Keep proper footing and balance

at all times.

• Never use in an area where flammable vapors are

present.

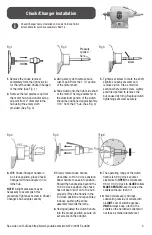

• Use proper grounding procedures. This tool

should be grounded while in use to protect the

operator from electric shock. The tool is equipped

with an approved 3-conductor cord and a 3-prong

grounding type plug to fit the proper grounding

receptacle. The green (or green and yellow)

conductor in the cord is the grounding wire. Never

connect the green (or green and yellow) wire to a

live terminal. If your unit is for use on less than

150 volts, it has a plug that looks like sketch

A below. An adapter (sketches B and C) can be

used for connecting plugs as shown in sketch

A to 2-prong receptacles. The green colored rigid

ear, lug, etc., Extending from the adapter must

be connected to a permanent ground such as a

properly grounded outlet box. Some jurisdictions,

including Canada, prohibit the use of 3 to 2

prong adapters. Where prohibited, they should

not be used. Use only 3-wire extension cords that

have 3-prong grounding type plugs and 3-pole

receptacles that accept the tool’s plug.

Thank you for Choosing the Handler Red Wing Lathe.

Open the package and inspect its contents.

The product has been inspected prior to being shipped. If damage has occurred in transit, contact

the carrier immediately. Do not contact the shipper as the customer receiving the product must file

a damage claim if necessary. Be certain to note any damage which may have occurred, and report

it promptly to the carrier. Failure to file a claim in a timely manner could result in the loss of your

rights of recovery for possible damages. Should you require assistance, please contact Handler

Manufacturing at

1-908-233-7796 or 1-800-274-2635.

Store your Handler tools in a DRY, clean, dust-free area, and out of the reach of children.

1. Never attempt to use a polishing motor without proper instruction.

2. Never use a polishing motor unless the motor has been fitted with polishing splash hoods or a similar protective

device containing a protective shield.

3. Always use a dust collector when performing polishing or grinding operations.

4. Read and follow all instructions contained in this manual regarding “tool safety.” Handler manufactures a full line of

Chucks, Splash Hoods, Dust Collectors, and Protective Shields. Contact us at the number below to request a Handler

Catalog or visit handlermfg.com

!

IMPORTANT