51

If FB is 3Hz, VC would be 400

÷

80

×

3 = 15 (V)

3. For safety reason, the recommended way to check V/F setting is to operate VFD without connecting motor. If the

ratio of output voltage and frequency is always equal to VMAX / FMAX, V/F setting could be finished.

4. Once VFD starts to drive motor, please check the output current at the beginning. Incorrect V/F setting would result

in an excessive current. If so, please shutdown VFD immediately and recheck all of the settings.

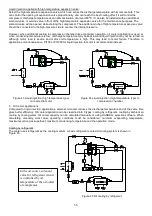

5.4 Compressor protection devices

The table below shows the list of protection devices which protects the compressor to operate safely. Apply protection

devices listed below to ensure your compressor could run under normal condition.

Protection device

Set point

Remark

Motor wiring temperature protector (PTC sensor) Cutout 110

℃

, cut in 100

℃

※

Standard

Discharge temperature protector (PTC sensor)

Cutout 110

℃

, cut in 100

℃

※

Standard

Oil level switch

Optional

Oil filter pressure differential switch

Cutout 1.5kg/cm

2

g

Optional

Oil flow switch

Optional

Pt100 or Pt1000 for liquid injection to motor

chamber.

Depends on applications. Normally the injection starts at 60

℃

and cut out at

50

℃

Optional

※

Manual reset suggested

Motor thermistors and discharge thermistors are temperature sensors with quick response while the temperature

approaches to their set point; thermistors must be connected in series to a controller (INT69HBY) in cable box as a

guardian to protect compressor. Alarm lamp for this protector is required to be embedded on control panel as indicator.

Any intention to short controllers for starting of compressors is prohibited. It is beyond Hanbell warranty of compressors

if any action mentioned is found.

Note: when any protection device trips, please do troubleshooting and reset manually. Do not let the compressor reset

automatically after any trip!

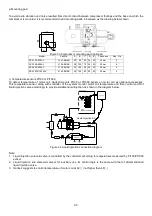

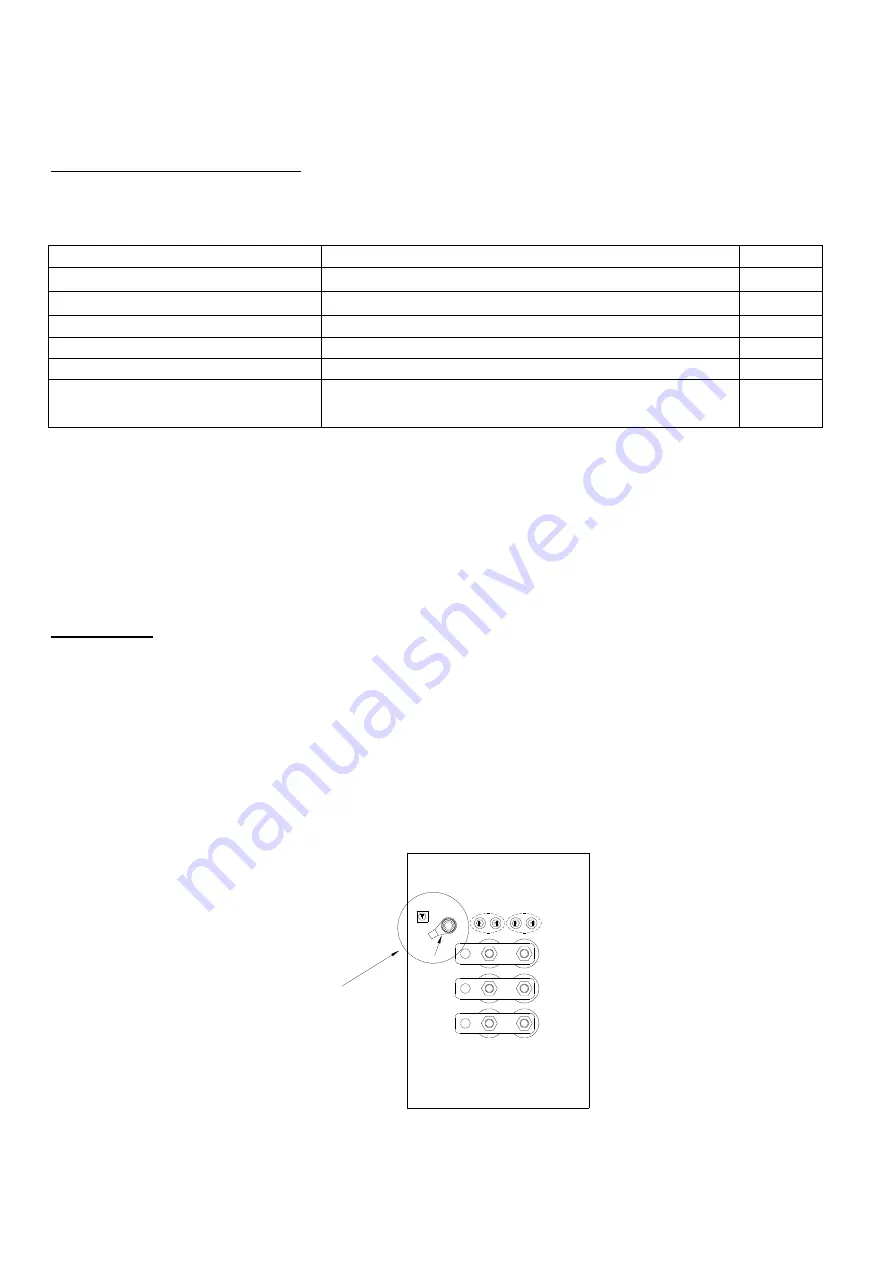

5.5 Grounding

There’s a grounding terminal on terminal plate. Please connect it to grounding of system control panel.

Suggestion:

a.

The regular setting of electric leak protection should be greater than 50mA; for humid locations, 25mA is

recommended.

b.

Grounding voltage of casing should be less than 50V; for humid locations, the maximum is 25V.

c.

Grounding resistance should be less than 500 Ohm.

d.

Air cut board (ACB) is regularly equipped with electric leak protection. Please refer to related settings for its

normal action.

e.

If electric leak protection is active, please check if insulation of equipments is normal and if its wiring and setting

are correct.

Grounding

B:Pt100

Ω

/ Pt1000

Ω

(Optional)

A:PTC

terminal

Earth Bolt

A

B

U

V

W

Figure 40 Grounding Terminal

Please make sure nothing is wrong before turning on power. If there are any questions, please contact the supplier of

equipments.

Содержание RC2-AV Series

Страница 15: ...4 3 RC2 AV series compressor outline drawings...

Страница 16: ...15...

Страница 17: ...16 UNIT SI mm Imperial in...

Страница 18: ...17...

Страница 19: ...18...

Страница 20: ...19...

Страница 21: ...20...

Страница 22: ...21...

Страница 23: ...22...

Страница 24: ...23...

Страница 25: ...24...

Страница 26: ...25...

Страница 27: ...26...

Страница 28: ...27...

Страница 29: ...28...

Страница 30: ...29...

Страница 31: ...30...

Страница 32: ...31...

Страница 33: ...32...

Страница 34: ...33 SI mm Imperial in UNIT...

Страница 35: ...34...

Страница 36: ...35...

Страница 37: ...36...