3.6

S

AFETY DEVICES

The excavator on which the CRUSHER is mounted must be equipped with the following safety devices:

DANGER

SECURITY DEVICE

Fall of material from above onto the

operator

FOPS cabin use

Accidental movements of the

CRUSHER

Circuits equipped with devices that block the equipment (e.g.

safety/non-return hydraulic valve) in case of sudden loss of

pressure/anomaly inside the hydraulic control circuit of the

CRUSHER.

3.7

R

ESIDUAL RISKS

Notwithstanding the safety devices listed in the previous paragraph, as well as the appropriate safety signs

applied on the equipment, the following residual may be identified in its use:

Danger area

Danger

Safety system adopted

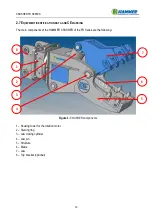

1

Jaw

Crushing

Impact

Make sure that no persons are within the

operating range of the equipment, and do not

interact manually with this component when

assembling/disassembling the equipment.

2

Rotation

Conveying

Impact

Make sure that no persons are within the

operating range of the equipment, do not

interact manually with this component when

assembling/disassembling the equipment.

3

Hydraulic circuit pipes

High pressure fluid ejection

Positioning of graphic safety signs, use of

components with a test certificate.

Use of appropriate Personal Protective

Equipment.

4

Machine and/or equipment

maneuvering area

Crushing

Impact

Fall of material from above

Dust inhalation

Make sure there are no people in the range of

operation or direction of the machine and/or

equipment.

Use a person to signal the movements to be

carried out.

FOPS cabin use

Use of appropriate Personal Protective

Equipment (e.g. dust masks).

24

CRUSHER FR SERIES