Intrinsically safe

PP1095/2021/Issue 6

Page 5 of 8

Safety earth

Shunt zener safety barriers must be connected to a high integrity

earth by at least one and preferably two copper cables, each of

cross sectional area of four mm2 or greater. The connection must

be such that the impedance from the connection point to the main

power system earth is less than one ohm.

Intrinsically safe circuits in the hazardous area should be insulated

from earth and must be capable of withstanding a 500V RMS ac

test voltage for at least one minute. When using armoured or

copper sheathed cables, the armour or sheath is normally isolated

from the safe area busbar.

Remote LED connection

A drive point is provided on each of the XP95 I.S. detectors for

a remote LED indicator. For connection details see Figure 3.

The

indicator must be a standard high-efficiency red LED and does not

require a series limiting resistor since current is limited within

the detector to approximately 1 mA. The remote LED cannot, as

in the standard XP95 range, be controlled independently from the

integral LED since it is effectively connected in series with the

integral LED. The benefit of this configuration is that illumination of

the remote LED does not increase the current drawn from the loop.

The system certification allows for the use of any LED indicator

having a surface area between 20 mm2 and 10 cm2 which

covers all commonly used case styles from T1 (3 mm) upwards

but would exclude some miniature and surface mounted types.

Additional requirements of the certification are that the LED and

its terminations must be afforded a degree of protection of at least

IP20 and must be segregated from other circuits and conductors

as defined in BS EN 60079-14.

The Apollo MiniDisc Remote Indicator (53832-070) is suitable

using connections B(+) and C(-).

Installation

It is important that the XP95 I.S. detectors are installed in such a

way that all terminals and connections are protected to at least

IP20 when the detector is in the base. Special care must be taken

with the rear of the mounting base where live metal parts (rivets)

may be accessible. Flush mounting of the base on a flat surface

will provide the required degree of protection.

If the base is mounted on a conduit box (e.g. BESA box or similar)

whose diameter is less than 85 mm then the base should be fitted

with a XP95 Backplate (Apollo part number 45681-233). Use

of the backplate will prevent access to the metal parts and will

also protect the rear of the base from water ingress. The conduit

box available from Apollo, part no. 45681-204, is also acceptable

for mounting I.S. bases. Apollo also supply a range of deckhead

mounting boxes.

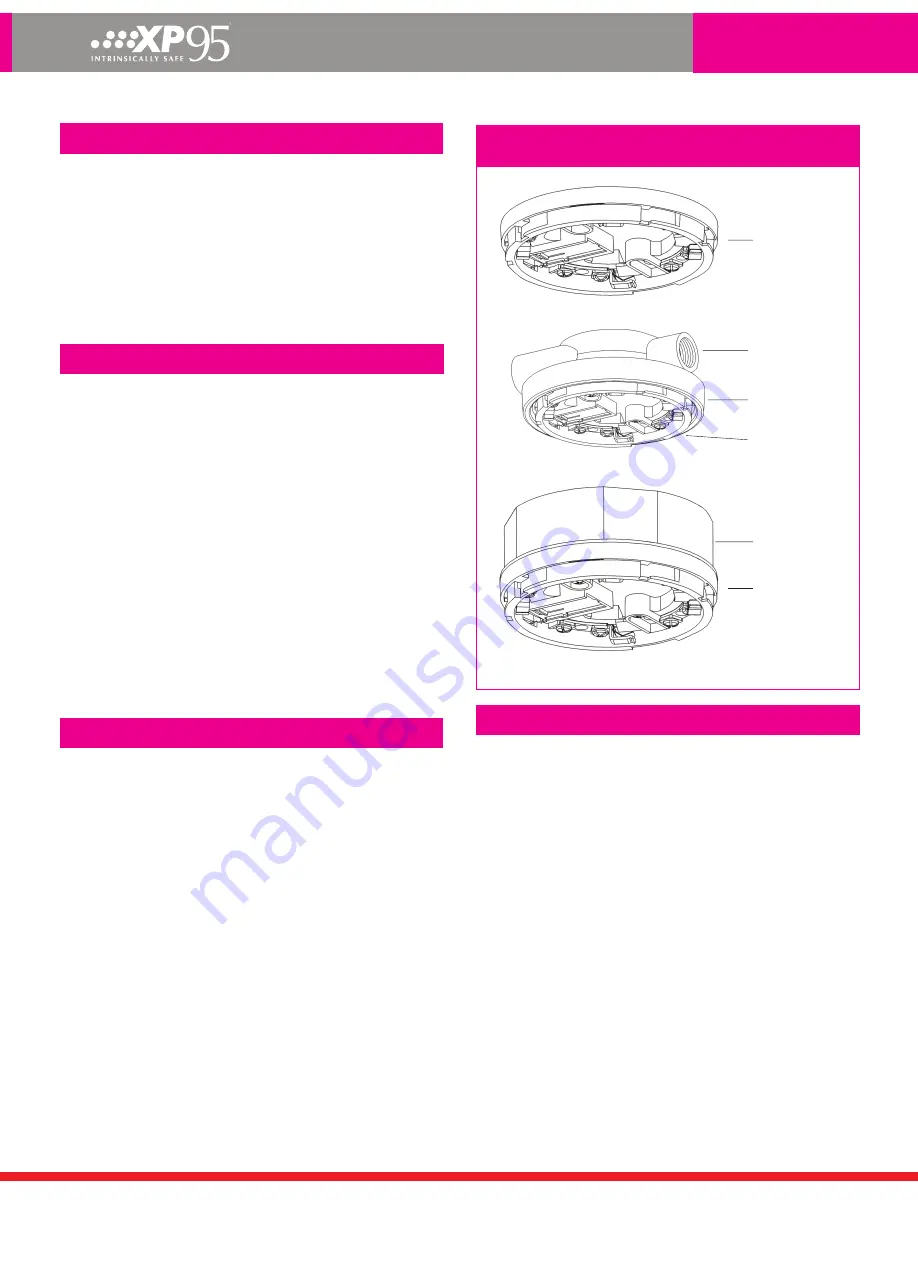

Figure 4 shows permissible methods of installing intrinsically safe

detector bases.

Note:

The earth terminal in the base is provided for convenience

where continuity of a cable sheath or similar is required. It is not

necessary for the correct operation of the detector nor is it provided

as a termination point for a safety earth.

Figure 4: Permissible methods of mounting I.S. detector

bases

Base fitted flush to soffit

I.S. Base

Part No. 45681-215

Base with backplate and BESA box

Standard

BESA box

Backplate

Part No. 45681-233

I.S. Base

Part No. 45681-215

I.S. Base

Part No. 45681-215

Conduit box

Part No. 45681-204

Base fitted to conduit box

Maximum loading of an I.S. circuit

The safety barrier is a mandatory part of an I.S. system, but the

high series impedance limits the number of I.S. detectors that may

be fitted to the circuit. Typically an I.S. circuit will have a maximum

load of about 15 detectors depending on the barrier type, the

type of devices fitted and the number of detector LEDs allowed to

illuminate concurrently by the Control and Indicating Equipment.

When calculating the detector load to ensure the I.S. detection

zone is not overloaded two components of the current drain must

be considered, namely the standing current of the devices by

themselves and the maximum drain caused by alarm LEDs being

illuminated.

The standing current of the devices can be calculated by taking the

sum of the individual device currents on the circuit, as given in the

section ‘Technical data’ for each product.

The maximum number of LEDs that can be illuminated

simultaneously should be limited by the panel software.

Table 5 and Table 6 show the maximum device current which can

be supported for varying numbers of LEDs illuminated for zener

and galvanic barriers respectively.