05-7150-00.fm

35

Maintenance and servicing

Hako system maintenance I

Every 250 hours or once a year

• Check proper functioning of the battery and charger

• Check the latching function of the battery

• Check the software versions, update if necessary

• Check leak tightness and proper functioning of the hoses (fresh and waste

water, suction turbine hose), replace if necessary

• Waste water tank:

Check the seal at the top of the sieve and the seal at the waste water inlet

• Check proper functioning of the suction turbine

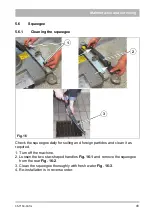

• Squeegee:

Check the folding function and ease of movement of the squeegee,

lubricate the joint locations if necessary

• Check the supporting rollers and the rollers as well as the lateral deflecting

rollers on the squeegee for ease of movement and wear, replace if

necessary

Attention! Do not loosen sealed screw connections of the supporting

rollers on the squeegee holder!

• Check the rollers and the lateral deflecting rollers on the chassis for ease

of movement and wear, replace if necessary

• Check the fresh water supply, replace worn parts if necessary

• Check proper functioning of the drive motor of the cleaning tools

• Check the rubber buffers for the drivers, replace if necessary

• Check the outer bow springs on both drivers for cracks. Cleaning tools

must run quietly and engage and disengage smoothly.

• Check proper functioning of the operating bar lock

• Check the ball joint for smooth steering and swivelling movement

• Check proper functioning of the textile strap of the operating bar relief and

the spring

• Check the optical condition of the machine (corrosion and labels)

• Carry out a function test