Page 58

31-5000723 Rev. 0

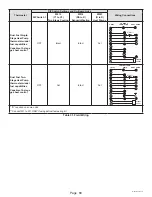

Typical Operating Characteristics

Blower Operation and Adjustment

1.

Blower operation is dependent on thermostat control

system.

2.

Generally, blower operation is set at thermostat subbase

fan switch. With fan switch in ON position, blower

operates continuously. With fan switch in AUTO position,

blower cycles with demand or runs continuously while

heating or cooling circuit cycles.

3.

Depending on the type of indoor thermostat, blower and

entire unit will be off when the system switch is in OFF

position.

Temperature Rise

Temperature rise for NF97UM units depends on unit input,

blower speed, blower horsepower and static pressure as

marked on the unit rating plate. The blower speed must be

set for unit operation within the range of “TEMP. RISE °F”

listed on the unit rating plate.

To measure temperature rise:

1.

Place plenum thermometers in the supply and return

air plenums. Locate supply air thermometer in the first

horizontal run of the plenum where it will not pick up

radiant heat from the heat exchanger.

2.

Set thermostat for heat call. Unit must operate on

second-stage heat. If using a single-stage thermostat

furnace must fire at least 10 minutes before switching to

second-stage heat.

3.

After plenum thermometers have reached their highest

and steadiest readings, subtract the two readings. The

difference should be in the range listed on the unit rating

plate. If the temperature is too low, decrease blower

speed. If temperature is too high, first check the firing

rate. Provided the firing rate is acceptable, increase

blower speed to reduce temperature.

External Static Pressure

1.

Tap locations shown in Figure 50.

+

-

Figure 50. Static Pressure Test

2.

Punch a 1/4” diameter hole in supply and return air

plenums. Insert manometer hose flush with inside

edge of hole or insulation. Seal around the hose with

permagum. Connect the zero end of the manometer to

the discharge (supply) side of the system. On ducted

systems, connect the other end of manometer to the

return duct as above.

3.

With only the blower motor running and the evaporator

coil dry, observe the manometer reading. Adjust blower

motor speed to deliver the air desired according to the

job requirements.

4.

External static pressure drop must not be more than 0.8”

W.C. in the heating mode and must not exceed 1.0” W.C

in the cooling mode.

5.

Seal the hole when the check is complete.