Page 35

31-5000723 Rev. 0

Venting Practices

* See table 2 for allowable pipe.

NOTE

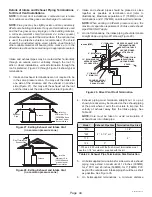

- Isolate piping at the point where it exits the outside wall or

roof in order to prevent transmission of vibration to the structure.

SCHEDULE 40

PVC - 5'

all other pipe* - 3'

Wall

e

d

i

s

t

u

o

e

d

i

s

n

i

24” maximum

3/4” minimum

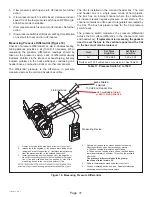

Wall Thickness Guidelines

NOTE -

ward unit a minimum of 1/4” (6mm) drop for each 12” (305mm).

Figure 20. Piping Suspension Guidelines

•

In areas where piping penetrates joists or interior walls,

hole must be large enough to allow clearance on all

sides of pipe through center of hole using a hanger.

•

When furnace is installed in a residence where unit is

shut down for an extended period of time, such as a

vacation home, make provisions for draining condensate

collection trap and lines.

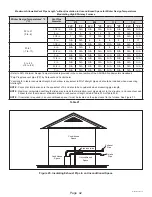

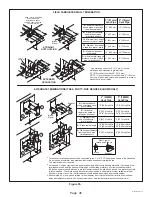

Exhaust Piping (Figure 21 and Figure 22)

Route piping to outside of structure. Continue with installation

following instructions given in piping termination section.

Intake Piping (Figure 21 and Figure 22)

The NF97UM furnace may be installed only in direct vent

applications.

The NF97UM is designed for combustion air intake through

an inlet in the unit’s top cap. Intake air piping is independent

of exhaust piping.

Do not discharge exhaust into an existing stack or

stack that also serves another gas appliance. If vertical

discharge through an existing unused stack is required,

insert PVC pipe inside the stack until the end is even

with the top or outlet end of the metal stack.

CAUTION

The exhaust vent pipe operates under positive pressure

and must be completely sealed to prevent leakage of

combustion products into the living space.

CAUTION