7

OPERATION MANUAL

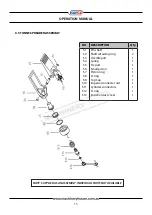

OPERATING INSTRUCTIONS

Before starting work, read and thoroughly understand all warnings and precautions in this

manual along with all documentation provided with the hydraulic ram kit, when in use.

INSPECTION, MAINTENANCE, AND CLEANING

1. Inspect the general condition of the Panel Beaters Repair Kit before each use,. Check

for bent, cracked, worn or damaged parts, loose or missing parts, and any other condition

that may affect the Kit’s safe operation. If a problem occurs, have the problem corrected

before further use.

Do not use damaged equipment.

2. To clean, use a damp cloth and a mild detergent or mild solvent. Do not use flammable or

corrosive agents.

3. The Panel Beaters Repair Kit when not in use should be stored in its carrying case and

kept in a clean, dry, safe location out of reach of children and other unauthorized people.

4.

CAUTION! If any maintenance, service, and repairs not discussed in this manual are required

seek help from a qualified service technician.

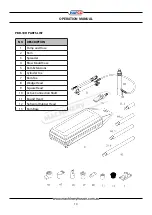

BASIC SETUP

The capacity of the Panel Beaters Repair Kit can be significantly affected by the number of

attachments used and the type of load applied. The load capacity of each function could

change when two or more extension tubes are used together. Be sure to position the shortest

tube further away from the ram

Note: Inspect before each use for evidence of fluid leaks, damaged hydraulic fittings, bent or

broken attachments and missing parts.

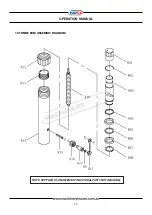

1. Locate and close the release valve by turning it clockwise until firmly closed. (Do not over

tighten)

2. Operate the pump by pumping the handle. This will send fluid from the pump reservoir into

the high pressure hose assembly and into the ram assembly.

3. Continue pumping until ram reaches desired height.

Note: Pump can be used in horizontal and vertical position.

To Release Pressure on the work piece:

Slowly, and carefully turn the release valve counterclockwise until the ram retracts to the

desired position. Never turn the release valve more than 1/2 full turn. The ram return system is

spring loaded, allowing for controlled retraction of the ram.

How to bleed air from system

1.

Bleed air from Ram:

Place the pump on a bench or table at a higher elevation than the hose

and ram. The objective is to get the air bubbles to rise and travel back to the reservoir.

2. Close the release valve and extend the ram as fast as possible. Open the release valve fully

allowing the oil and air to return to the reservoir. Repeat this procedure two or three times.

3.

Bleed air from pump:

With the ram fully retracted, remove the oil filler screw to let the

pressurized air escape, then reinstall oil filler screw.

OPERATION