Manager:

Metal Cutting Bandsaw

LOW

CRUSHING

Authorised and signed by:

Developed in Co-operation Between

A.W

.I.S.A

and

Australia Chamber of Manufactures

This program is based upon the Safe W

ork

Australia, Code of Practice - Managing Risks of Plant in the W

orkplace ( WHSA

201

1 No10 )

O

NEW

MACHINER

Y

HAZARD IDENTIFICA

TION,

ASSESSMENT & CONTROL

If blade breaks do not open door until both wheels have stopped.

Safety of

ficer:

Remove all loose objects around moving parts.

Machine should be installed & checked by a Licensed Electrician.

PLANT SAFETY

PROGRAM

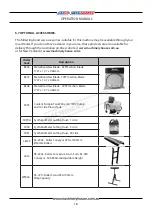

No.

Hazard

Identification

Item

Hazard

Assessment

SHEARING

B

D

ENT

ANGLEMENT

CUTTING, ST

ABBING,

H

PUNCTURING

MEDIUM

Blade guards should always be in the closed position before starting machine.

A

C

HIGH

Risk Control Strategies

(Recommended for Purchase / Buyer / User)

Secure & support Long / heavy material

Eliminate, avoid loose clothing / Long hair etc.

W

ear gloves when changing blades.

Check blade tracking before starting.

Blade guide system should be adjusted to suit material width.

MEDIUM

W

ear safety glasses

Isolate power to machine prior to changing belts or maintenance.

Stand clear of machine when in operation.

MEDIUM

ELECTRICAL

F

STRIKING

LOW

Support long heavy jobs and stand clear of of

fcuts.

OTHER HAZARDS, NOISE.

LOW

All electrical enclosures should only be opened with a tool that is not to be kept with the machine.

W

ear hearing protection as required.

Make sure all guards are secured shut when machine is on.

Revised Date:

www

.machineryhouse.com.au

www

.machineryhouse.co.nz

12th March 2012

Isolate main power switch before changing blade, cleaning or adjusting.

Plant Safety Program to be read in conjunction with manufactures instructions

Содержание MetalMaster BS-5S

Страница 23: ...23 OPERATION MANUAL BS 5S PARTS DIAGRAM ...