5.52.131

14.4

Low

m

Regu

Exch

Short

pollut

Lubri

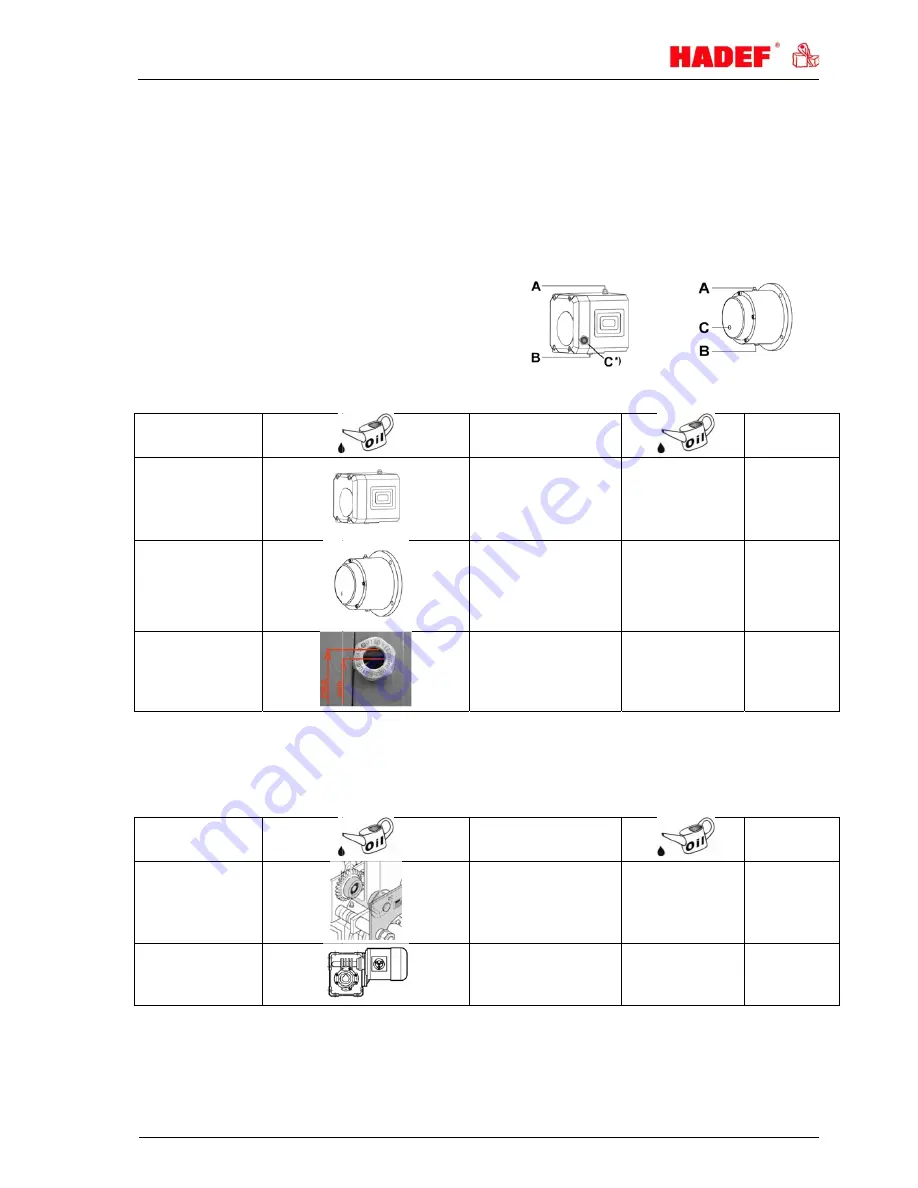

A = Oil fi

B = Oil d

C = Oil le

*) only b

14.5

Trolle

Lubri

14.6

For the

lubricatio

A high te

Use

Spur gea

Planetar

Spur gea

Planetar

Use

Pulleys

Gear rim

Drive pin

Travellin

If availab

1.00.01.09

Hoist gea

maintenance

ular lubricant

ange synthe

ter maintena

tion loads or

cant: synthe

ill in or air dis

drain plug

evel glass

y explosion p

Trolley

eys are lifetim

cate gear rim

Electric m

e motor it is

on status.

emperature f

ar

ry gear

ar *)

ry gear

m

nion

ng gear

ble

ar

e.

checks requ

etic lubricants

ance interva

constant op

tic, viscosity

scharge scre

proof electric

me lubricated

m and pinion

motor

s sufficient t

fat must be u

uired

s after 3 year

als for partic

eration of the

VG 220

ew

cal equipmen

d, Refill lubric

drive each ¼

to keep the

used if the ro

rs

cularly diffic

e hoist with t

nt

cant is norma

¼ year or if r

cooling airw

ller bearing i

R

FUC

RE

FUC

RE

R

FUC

RE

SH

Tive

ult operating

the highest lo

AK4 –

Illustration

ally not nece

required mor

ways clean

is replaced.

Recommend

CHS

NOLIN PG 2

CHS

NOLIN PG 2

Recommend

CHS

NOLIT FEP2

ELL

ela S320

g conditions

oad

– AK8

24

essary.

e often, with

and monitor

ation

220

AK

AK

AK

AK

220

AK

A

Ma

= g

Min

= g

ation

2

s, e.g. incre

A

grease.

r the roller b

K/AP4 – 0,45

K/AP6 – 1,00

K/AP7 – 1,90

K/AP8 – 1,90

K/AP9 = 0,35

AK/AP10 = 3

aximum fill lev

gauge full fille

nimum fill lev

gauge half fill

0,1 kg

---

ased dust a

AK9+AK10

bearing and

Inter

5 l

0 l

0 l

0 l

Lubric

chan

3 yea

5 l

l

Lubric

chan

3 yea

vel

ed

vel

led

Inter

3 mo

Life ti

lubrica

25

and

its

rval

cant

nge

ars

cant

nge

ars

rval

onth

ime

ation