Option

Description

Tubing life

Set a reminder when the pump tubing is to be changed. Go to ENABLE>RESET

CYCLES to reset the pump cycle count to 0. Go to ENABLE>CYCLE LIMIT to change

the number of pump cycles that is used for the reminder. Go to ENABLE>STATUS to

show the current number of pump cycle counts.

SDI–12 (optional)

Configure the operation of an SDI–12 device. This option is shown only when a device is

found.

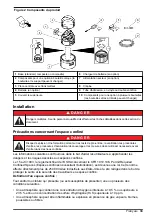

Set up a sampling program

A sampling program includes all of the parameters that are necessary to collect samples

automatically. Collect the samples at regular intervals or when the sampling program is complete.

1.

Push

MENU

.

2.

Go to PROGRAM SETUP>MODIFY ALL. The first screen is shown.

3.

Select or enter the values for each parameter. Use the left and right arrow keys to move left or

right. Use the up and down arrow keys to change a value. Change the units if necessary (gal or

mL) with the arrow keys.

Option

Description

Bottles

Bottle quantity: the number of bottles in the sampler (1, 2, 4, 8 or 24).

Full BTL shutoff: Enabled/Disabled. If enabled, the controller checks for bottle

overflow conditions.

Bottle volume: the volume capacity of each bottle. Range: 50–65000 mL (0.01 -

17.17 gal)

Intake tubing

Tubing length: the length of the intake tubing from the strainer to the liquid sensor.

Range: 100–3000 cm or 3–99 ft. An accurate length is necessary to get an accurate

sample volume.

Intake tube type: the diameter and material of the intake tubing (¼ in. vinyl, 3/8 in.

vinyl or 3/8 in. Teflon).

Program delay

Enable/disable: when enabled, the sampling program starts at a specified time or

number of counts. Date and time: the date and time when the program starts (24-

hour format). Counts: the number of counts or pulses from a flow meter when the

program will start (1 to 9999 counts). If the sample pacing is later set to time, the

program delay will be disabled.

Sample

pacing/collection

Time based—Refer to

on page 19.

Note: When CTVV is used:

•

The liquid sensor is always enabled.

•

The sample distribution is composite.

•

The run mode is non-continuous.

•

The first sample is taken after the interval.

•

Flow source is always 4–20 mA input.

Sample distribution

Deliver samples to all>YES

Each sample is delivered to all bottles. End after last: program stops after the last

sample (1–999). Continuous: program continues until it is stopped manually.

Deliver samples to all>NO

Samples are delivered to a subset of bottles . Samples/bottle: the number of samples

to be collected in each bottle (1–999). Bottles/sample: The number of bottles that will

contain the same sample.

Liquid sensor

Enable or disabled. If disabled, the sample volume must be calibrated by time.

18

English

Содержание SD900

Страница 2: ...English 3 Fran ais 28 Espa ol 54 Portugu s 80 106 129 153 2...

Страница 25: ...English 25...

Страница 103: ...Portugu s 103...

Страница 109: ...FCC 15 A 1 2 3 4 5 SD900 1 1 1 6 2 7 3 8 4 9 5 10 21 L 5 5 gal 2 109...

Страница 110: ...2 1 6 2 7 3 8 4 9 5 10 1993 4 15 OSHA CFR 1910 146 Permit Required Confined Spaces 250000 19 5 23 5 H2S 10 ppm 110...

Страница 111: ...110 106 111 114 106 1 111 2 3 111...

Страница 113: ...4 1 1 1 6 2 1 24 7 21 L 5 5 gal 3 1 8 8 4 1 2 4 9 5 1 111 2 1 112 3 5 8 4 8 113...

Страница 115: ...6 1 3 2 7 8 115...

Страница 116: ...8 1 4 SDI 12 2 5 3 Sigma 980 980 1 980 980 2 6 6 7 7 RS232 DB 9 9 B 5 D 3 RCD F 2 TXD G 1 2 9 GFCI GFI 116...

Страница 117: ...15 A 117 1 2 10 3 117...

Страница 118: ...10 50 C 122 F 1 3 5 15 2 11 MENU ENTER BACK 118...

Страница 125: ...12 1 12 2 3 4 5 O 6 12 1 3 O 2 4 125...

Страница 126: ...4 6 m 15 2 m 15 ft 50 ft 1 2 3 4 5 126...

Страница 127: ...126 127...

Страница 128: ...1 2 13 3 4 13 1 3 5 2 4 128...

Страница 131: ...Web IECS 003 A 131...

Страница 133: ...1 1 6 2 7 3 8 4 9 5 10 21 L 2 HACH Japan 2 1 6 2 7 AC 3 8 4 9 5 10 133...

Страница 134: ...1993 4 15 CFR 1910 146 Permit Required Confined Spaces OSHA 250 000 1 19 5 23 5 H2S 10 ppm 134 129 135 137 129 134...

Страница 135: ...Web 1 1 135 2 3 3 1 10 L 1918 6 21 L 6494 2 10 L 6559 7 8975 3 1502 8 8976 4 15 L 1367 9 21 L 8561 5 19 L 6498 2 4 135...

Страница 136: ...1 5 137 4 1 1 1 6 2 1 24 7 21 L 3 1 8 8 4 2 2 4 9 5 1 135 2 1 135 3 5 8 1 4 8 136...

Страница 138: ...6 1 3 2 7 8 138...

Страница 139: ...8 1 4 SDI 12 2 5 3 Sigma 980 980 1 980 980 2 6 6 7 PC PC 7 RS232 DB 9 9 B 5 D 3 RCD F 2 TXD G 1 2 9 139...

Страница 140: ...GFCI GFI 15 A PE 141 AC 140...

Страница 141: ...1 2 10 3 10 50 C 1 3 5 15 2 AC 11 MENU ENTER BACK 141...

Страница 149: ...12 1 12 2 3 4 5 O 6 12 1 3 O 2 4 149...

Страница 150: ...4 6 m 15 2 m 1 2 Web 3 4 5 150...

Страница 151: ...150 151...

Страница 152: ...1 2 13 3 4 13 1 3 5 2 4 152...

Страница 155: ...IECS 003 A 155...

Страница 157: ...1 1 6 2 7 3 8 4 9 5 10 21 L 5 5 gal 2 2 1 6 2 7 AC 3 8 4 9 Teflon 5 10 157...

Страница 158: ...XXX 1993 4 15 OSHA CFR 1910 146 250 000 19 5 23 5 H2S 10 ppm 158 153 159 161 153 158...

Страница 160: ...4 1 1 1 6 2 24 1 7 21 L 5 5 gal 3 8 1 8 4 2 4 1 9 5 1 159 2 1 159 3 5 8 1 4 8 160...

Страница 162: ...6 1 3 2 7 8 162...

Страница 163: ...8 1 4 SDI 12 2 5 3 Sigma 980 980 2 1 980 980 2 6 6 7 PC PC 7 RS232 DB 9 9 B 5 D 3 RCD F 2 TXD G 1 2 9 163...

Страница 164: ...GFCI GFI 15 A PE 165 AC 164...

Страница 165: ...1 2 10 3 10 50 C 122 F 1 3 5 15 2 AC 11 MENU ENTER BACK 165...

Страница 168: ...0 3 0 3 ID 12 ID 1 0 01 999 00 168 169 CTVV 1 MAP 4 mA 4 mA MAP 20 mA 20 mA 1 999 999 10 10 000 ml 168...

Страница 172: ...0 1 MANUAL OPERATION 2 GRAB SAMPLE 3 4 5 6 7 ENTER 8 172...

Страница 173: ...12 1 12 2 3 4 5 6 12 1 3 2 4 4 6 m 15 2 m 15 ft 50 ft 1 2 3 4 5 173...

Страница 174: ...174...

Страница 175: ...173 1 2 13 3 4 13 1 3 5 2 4 175...

Страница 176: ......

Страница 177: ......