12.3. Maintaining the primary air limiter

The primary air limiter (PAL) is inserted at the back or

the side of the inner stove (see Figures 1, 2 and 19). A

pendulum flap is located inside the automatically

operating PAL. The PAL serves for the economical

heating of your stove. To make the PAL accessible, the

rear wall (“Viking”) or the inspection panel (“Ibiza”) of

your oil stove must be removed. Lightly compress the

housing with the hand so that the PAL can be pulled

out from the preheating chamber (see Figures 1 + 2).

Remove any dust that may be present using a vacuum

cleaner. To install, simply insert the PAL snugly in the

existing opening in the burner jacket (important: Large

round section must be at the bottom, see Figure 19).

Following this, ensure the unobstructed movement of

the pendulum flap by tapping on it carefully. The flap

could be jammed due to vibrations during the transport

of the stove or suchlike. Such a condition must be

rectified.

12.4. Cleaning the appliance surfaces

The view window pane and the painted surfaces of the

appliance are best cleaned with warm water and soap

or other commercially available cleaning agents. Do not

use any abrasive cleaning agents as this would

damage the glass and also the metal surfaces by

scratching. Clean the painted parts only with the stove

in cold condition to prevent the formation of cracks or

stains.

12.5. Maintaining the electric ignition

As already mentioned at the beginning of this

chapter, always pull the power plug whenever

working on the appliance!

Work on the electric units of the appliance must only be

carried out by the works service or trained technical

personnel except for the following.

Replacing the ignition bar:

The ignition bar can be easily replaced on the oil stove

with electric ignition. A defect on the ignition bar can be

identified in that the ignition coil

fails to glow

with cold

stove and ignition switched on. This can be verified

through the opened fire chamber door.

1. Disconnect inspection panel.

2. Disconnect the two cables (supply line) from the

ignition bar (Figure 17).

3. Loosen the two mounting screws of the retaining

plate (see figure 24) and remove the retaining plate

with a short anti-clockwise movement.

4. Pull the ignition bar from the burner by lightly

turning 90°.

5. It is imperative to secure the glass fibre seal

(approximately 2

– 3 mm diameter, see Figure 24),

around the new ignition bar, to completely seal the

hole.

6. Place the tension spring on the ignition bar.

7. Install the ignition bar in reverse order (4. to 1.).

Please note that the cables on the connection

terminals of the ignition bar are screwed on tightly

to ensure sound electrical contact.

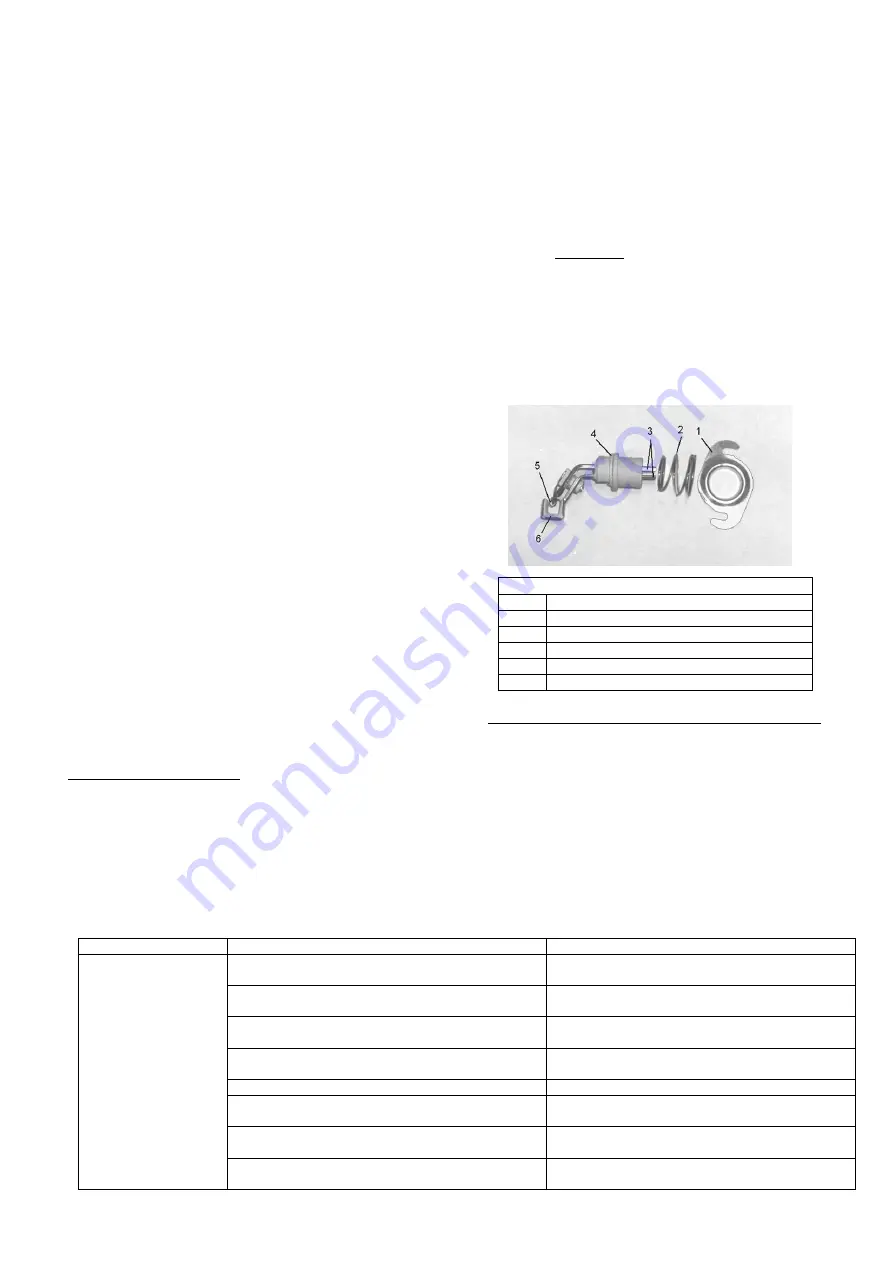

Figure 24:

Ignition bar components

1

Retaining plate

2

Compression spring

3

Connection terminals

4

Glass fibre seal

5

Ignition coil

6

Evaporator coil

Replacing the microfuse in the ignition transformer:

Disconnect the inspection panel. The microfuse is

integrated in the ignition transformer. To replace it,

merely insert a screwdriver in the screw cap and

remove the cap (see Figure 16). The fuse has the

following rating:

M 500 mA, 250 V.

13.

Problem solutions

– what to do if... ?

In the following table we have listed some problems, their cause and proposed remedies. Because of the wide range of

possible fault causes the list cannot be complete. If you cannot rectify the malfunction of the appliance with this list,

consult your specialist dealer.

Problem

Reason

Solution

-

Insufficient

oil

stove draught

-

Flue gas escapes

upon igniting or

shortly thereafter

and/or during the

heating phase

-

Soot deposits in

the oil stove

Chimney or flue gas pipe are leaking

Clarify with chimney-sweeper, on flue pipes,

check tight joints and reseal if required

The flue pipe connection between oil stove and

chimney is unfavourable.

See Chapter 9. “Connection to the chimney”

Chimney incorrectly dimensioned.

Clarify with chimney-sweeper: possibly increase

chimney or fit chimney attachment.

A door of other fireplaces connected to the

chimney is open.

Close the doors of other fireplaces.

Chimney cleaning openings are open.

Close these cleaning openings.

Appliance, flue pipes or chimney are sooted-up or

clogged.

See Chapter 12. “Cleaning and maintenance”.

Slag in the area of the burner base

Clean burner, especially pierce open the air

holes in the burner wall (see Chapter 12.1.)

Insufficient fresh air supply.

See Chapter 2. “General information, safety

instructions”.