11

4.04

Maintenance which should be carried out by the owner?

Check at regular intervals that the lifting strap has no damages. If the lifting

strap is damaged, DH 1000 should not be used. The lifting strap must only be

exchanged by an authorized installer.

5.00

Service and Life Span

5.01

Life span and servicing

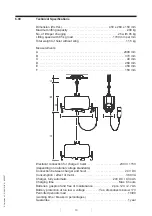

According to the international standard EN/ISO 10535 “Hoist for the transfer

of disabled persons - Requirements and test methods” a safety inspection of

the hoist must be performed at least once a year.

DH 1000 has an expected life span of 15 years. The hoist must then be

assessed by qualified service staff as to its future use.

Spare parts lists and drawings are available from manufacturer or supplier.

5.02

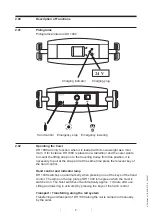

Battery and fuses

Change of batteries and fuses should be carried out by a service engineer or

by the Guldmann Service Team.

5.03

Service check

During the inspection a service report shall be made, describing what has

been checked and exchanged.

Worn or defective parts shall be replaced by new spareparts from

V. Guldmann A/S.

1 Visual check of the product.

• Check the product for wear and tear

• Check the product for any deformity

• Check that the product does not show any other dificiencies.

2 Test of the product, as during normal use.

• Check all functions on the product, with and without load,

( eg. Up, down, forward, backward, out and in ).

• Check the emergency lowering is operational.

• Check the emergency stop is operational.

• Check the charging indicator is operational.

3 Dismantle the cover / fence.

4 Check the electrical condition of the products

• Check the batteries and measure the:

• Input / Voltage

• Output / Voltage

• Check electrical functions and signals

• Check all wirings for errors and defects

• Check wire lead-ins

• Check all possible conections, plugs etc.

©

G

ul

dm

an

n

U

S

-8

90

/0

1/

06

•

#

90067

©

G

ul

dm

an

n

U

S

-8

90

/0

1/

06

•

#

90067

Содержание 12071

Страница 1: ...GB US DH 1000 ...