CLEANING SPARK ARRESTOR SCREEN

If the engine exhaust muffler has a spark arrestor screen,

inspect and clean the screen

every 100 hours

of operation

or once each year, whichever comes first.

NOTE:

If you use your engine on any forest-covered, brush-

covered or grass-covered unimproved land, it must have a

spark arrestor. The spark arrestor must be

maintained in good condition by the owner/operator.

Clean and inspect the spark arrestor screen as follows:

Inspect the screen and replace if it is torn, perforated or

otherwise damaged.

DO NOT USE

a defective screen. If the

screen is not damaged, clean it with a commercial solvent.

If the spark arrestor is found to be damaged or defective, replace it.

SERVICE AND ADJUSTMENTS

ENGINE SPEED

CAUTION:

The engine speed was properly adjusted at

the factory and should require no additional adjustment. Do

not attempt to change engine speed. If you believe the

engine is running too fast or too slow, take your engine to

an authorized service center for repair and adjustment.

CHANGING THE ENGINE GOVERNED SPEED

WILL VOID THE ENGINE WARRANTY.

The operating speed of this engine is maintained by either a

mechanical, flyweight type or an electronic stepper motor

controlled governor.

DO NOT

try to adjust the governed

speed setting for the following reasons:

•

Operating the engine at high engine speeds is dangerous

and increases the risk of personal injury or damage to the

equipment.

•

Operating the engine at low engine speeds with heavy

loads may shorten the engine’s life.

CARBURETOR ADJUSTMENTS

The carburetor of your engine is pre-set at the factory. The

carburetor should not be tampered with because this will

VOID THE EMISSION CONTROL SYSTEM

WARRANTY

. If you experience problems and your engine is

used at an altitude in excess of 5000 feet, contact the nearest

authorized dealer regarding high altitude setting changes.

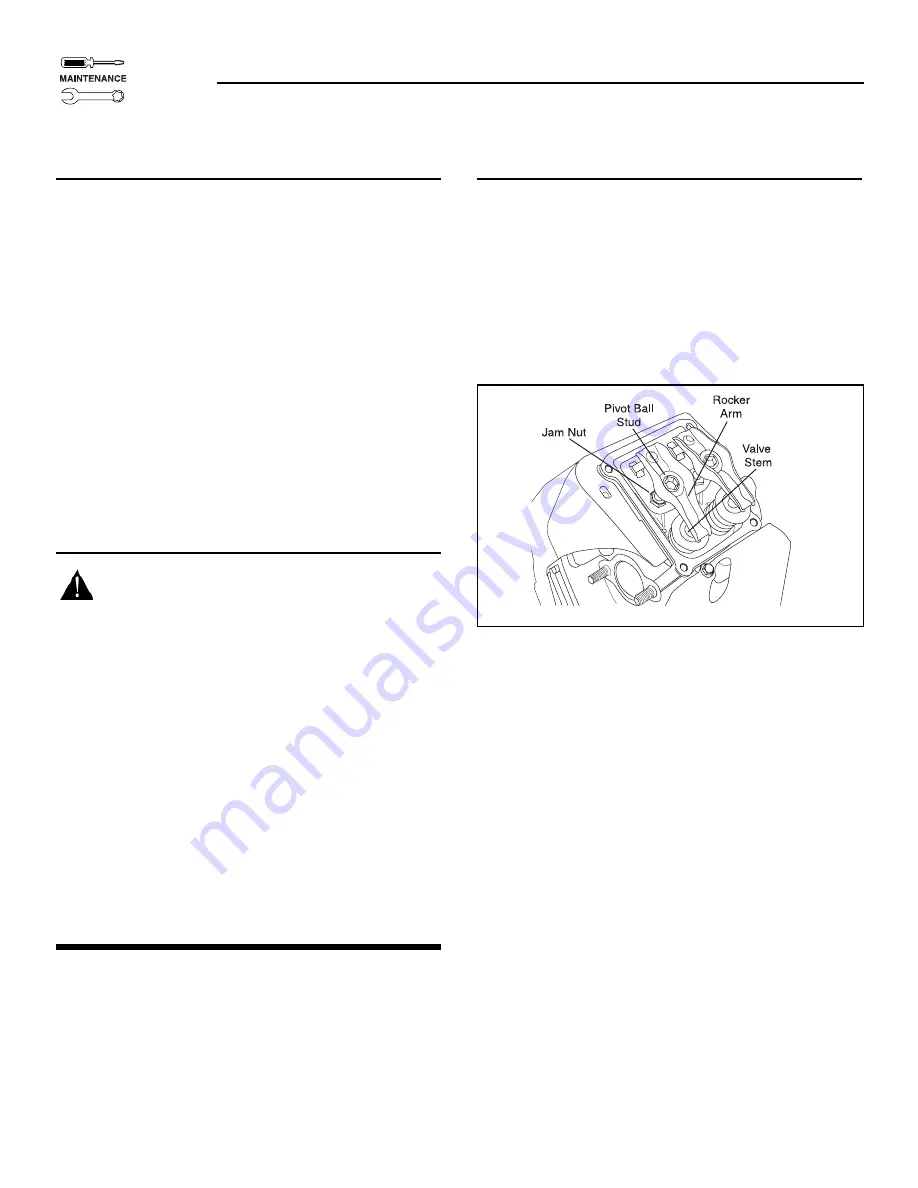

ADJUSTING VALVE CLEARANCE

After the first 100 hours of operation, you

should adjust the valve clearance in the engine.

IMPORTANT:

If you feel uncomfortable about doing this

procedure or you don't have the proper tools, please take your

engine in to the nearest service center to have the valve

clearance adjusted. This is a very important step to insure

longest life for your engine.

To adjust valve clearance:

• Make sure the engine is at room temperature.

• Make sure that the spark plug wires are removed from the

spark plugs and out of the way.

• Remove the four screws attaching the valve cover with

a 10 mm wrench or socket.

• Make sure the piston is at Top Dead Center (TDC) of its

compression stroke (both valves closed). To get the

piston at TDC, remove the intake screen at the front of

the engine to gain access to the flywheel nut. Use a large

socket and socket wrench to rotate the nut and hence the

engine. While watching the piston through the spark plug

hole. The piston should move up and down. The piston is

at TDC when it is up as high as it can go.

• Loosen the rocker jam nut. Use an 10mm allen wrench

to turn the pivot ball stud while checking clearance

between the rocker arm and the valve stem with a

feeler gauge. Correct clearance is 0.002-0.004 inch

(0.05-0.1mm).

NOTE:

You must hold the rocker arm jam nut in place as you

turn the pivot ball stud.

Figure 10 - Valve Clearance Adjustment

10

GTV/GTH - 990/760 OHVI SERIES ENGINES