www.allpaxcorp.com

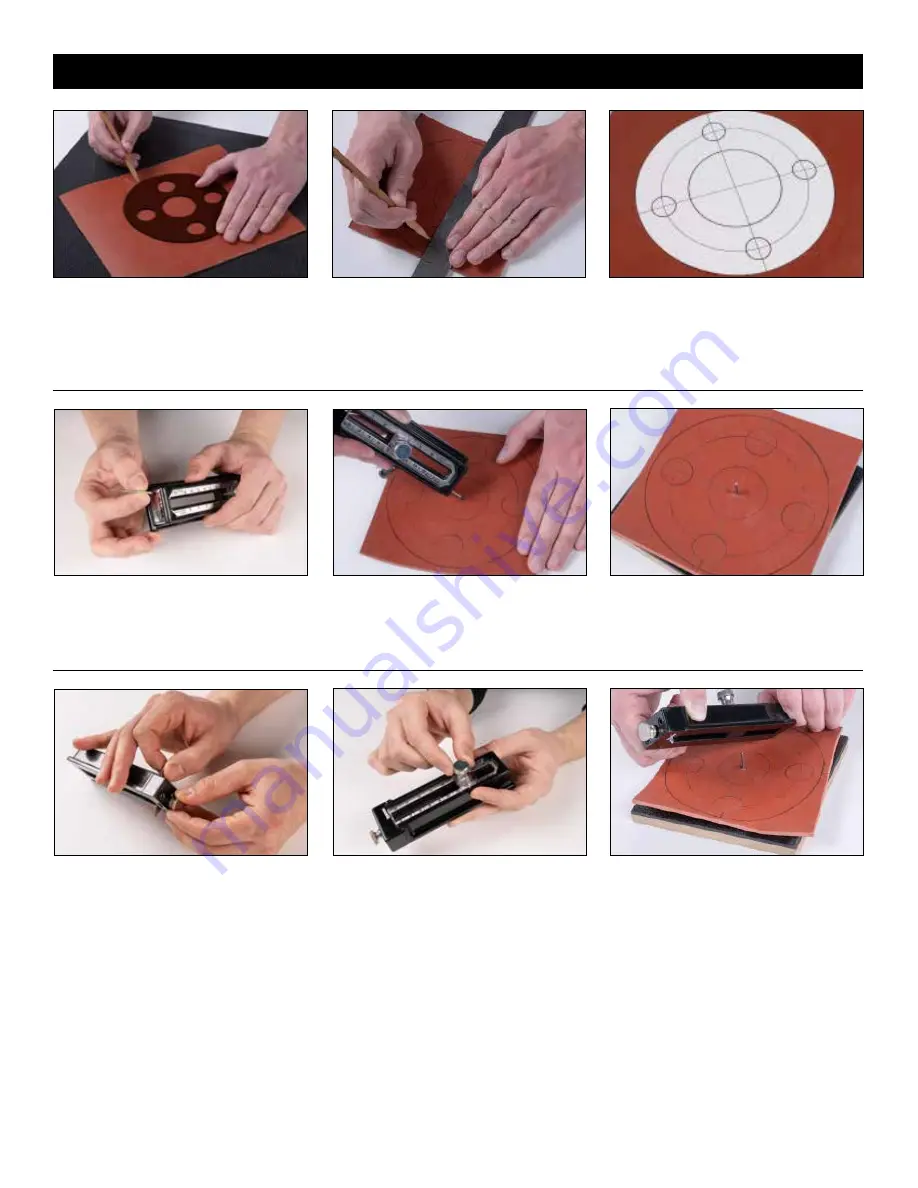

CUT GASKETS UP TO 6” (152 mm) DIAMETER

8.

8.

Loosen top thumb screw. Slide pivot post ind-

cator to desired OD on cutter block scale. Tighten

top thumb screw.

5.

5.

Using cutter block as a handle, pierce center of

gasket material with center pin. Disengage cutter

block leaving center pin protruding through gasket

material.

6.

6.

Insert protruding center pin into recessed

ferrule located in the center of cutting board.

Lay gasket material flat on cutting board.

7.

7.

Loosen cutting blade thumb screw on cutter

block. Position cutting blade to protrude slightly

beyond thickness of gasket material. Tighten

thumb screw.

(continued on next page)

1.

1.

If existing gasket is available, use a pencil to

trace outline onto gasket material.

3.

3.

Another way to determine bolt hole locations

is using a paper template with OD, ID and PCD.

Transfer the bolt hole location center pins with

piercing tool or pencil tip.

4.

4.

Choose center pin approximately ½” (12 mm)

longer than thickness of gasket material. Insert

center pin into silver hole at end of cutting block.

2.

2.

Otherwise, lay out outer diameter (OD), inner

diameter (ID) and pitch circle diameter (PCD)

directly onto gasket material. To determine bolt

hole locations see

LAYING OUT GASKETS WITH

BOLT HOLES.

9.

9.

Position pivot post hole over center pin.

Ensure cutter block is lying flat on gasket material.