CUC 2005

Abgleich / Alignment

GRUNDIG Service

2 - 3

GB

Alignment

Attention!

1. After any repair or replacement of NVM (IC82005) check whether the NTSC 3.58MHz quartz (Q34044, page 3-3) is fitted. If it is not, the dialog

line "NTSC 3.6" in the Service Menu must be set to "off".

Button "

6

" –> "OK" –> SERVICE –> "OK" –> SERVICE Code "8500" –> NTSC 3.6 "off" and in dialog line "END" store the setting "with mem.".

All adjustment controls not mentioned in this description are pre-set at the factory and must not be re-adjusted in the case of repairs.

Chassis Board

Measuring instruments: Digital voltmeter, colour video generator, spectrum analyser, RF millivoltmeter

Service works after replacement or repair of the following modules:

- Power supply: alignment 1.

- Tuner: alignment 2.

- IF, video demodulator: alignment 2.

- CRT, CRT panel: alignment 7…9.

- Deflection: alignment 9.

- NVM IC82005: alignment 2…7., 10…11.

Adjust R60037 on the chassis board and R60414 on the

"Module Mains Unit 12V" in 12V operataing mode according

to the table on the "Circuit Diagram Mains Section".

Adjust 102dB

µ

V (360mV

pp

) with button

4

or

3

.

Alternatively, without using a spectrum analyser or RF

millivoltmeter, adjust the picture with button

4

or

3

so

that noise just appears on the screen. Then reset until the

picture is again free of noise.

Terminate the dialog line "End" "with mem.".

With button

4

or

3

position the menu in the middle of the

picture.

Terminate the dialog line "End" "with mem."

.

With button

4

or

3

enter the correct screen diagonal.

Terminate the dialog line "End" "with mem."

With button

4

or

3

select "off".

Terminate the dialog line "End" "with mem."

With button

4

or

3

select "on " for models with NTSC or

"off" for models without NTSC.

Terminate the dialog line "End" "with mem."

With button

4

or

3

set the values for "Green" and

"Blue" so that the picture becomes achromatic.

Check this alignment at minimum and maximum contrast.

Go back to the "SERVICE" menu with "

6

" and terminate

the dialog line "End" "with mem.".

With adjustment control U

G2

, adjust the line appearing

first - red, green, blue or mixed-colour - so that it is just

well visible.

Return to the menu with "OK".

With focus control U

F

, adjust the vertical lines approx.

5cm from the right and left picture edge to minimum

horizontal width.

The sharpness in the middle must not seem to be worse

than the sharpness at the edges. If necessary, take an

average.

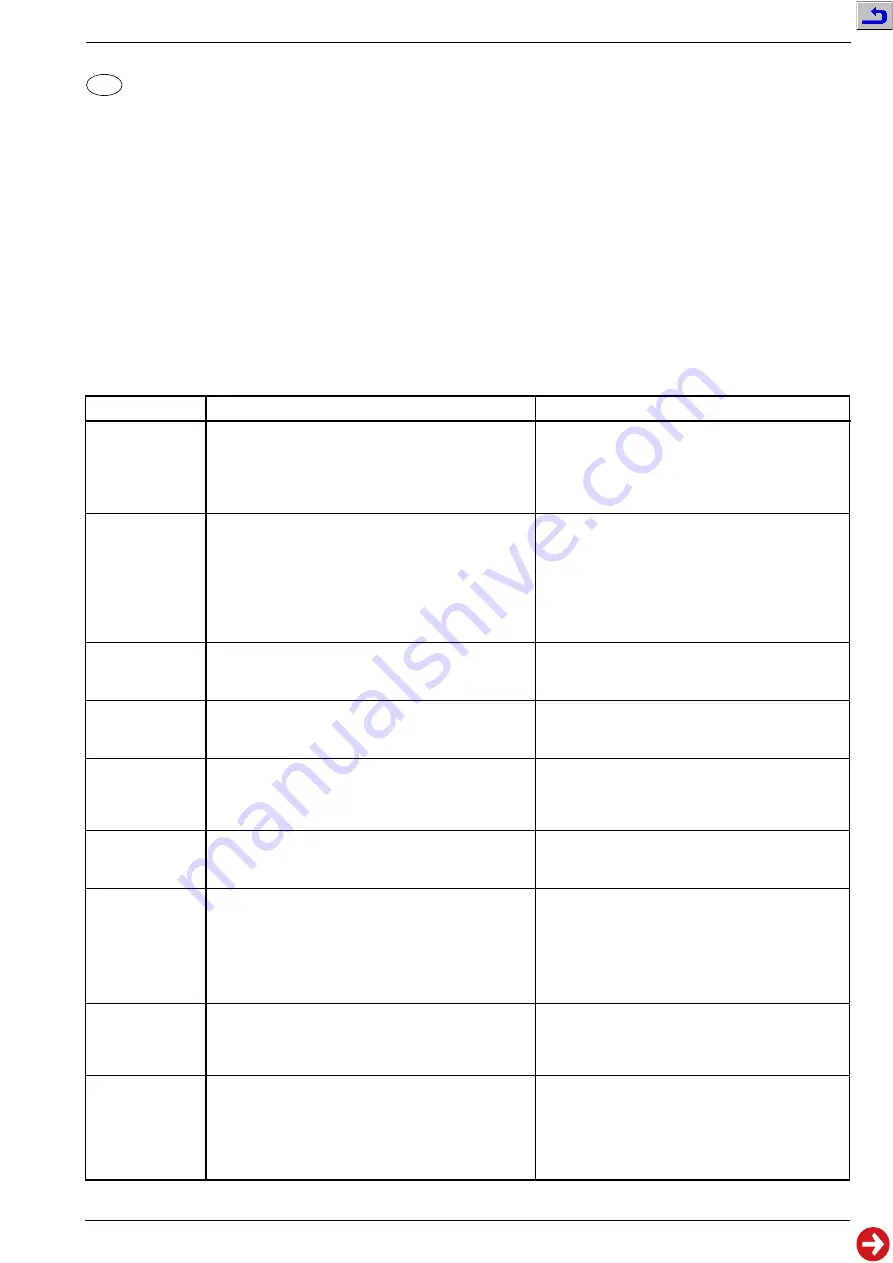

1. +A voltage

2. Tuner AGC

3. OSD

4. Tube

(Type of picture

tube)

5. Overscan

(switch-off

behaviour of

tube)

6. NTSC 3.6

7. White Balance

8. Cut-off Align

(screen grid

voltage U

G2

)

9. Line Sharpness

This voltage must be checked and re-adjusted if necessary

after every repair and before every alignment.

Brightness: Minimum

Digital voltmeter: Cathode D61016

Spectrum analyser or RF millivoltmeter unsymmetrical to

tuner contact 10, 11.

Feed in a standard test pattern or generator via the aerial,

70…80dB

µ

V.

Call up the dialog line "AGC" via "

6

" (DIALOG CENTER) –>

"OK" –> SERVICE –> "OK" –> Service Code "8500".

Call up the dialog line "OSD" via "

6

" (DIALOG CENTER) –>

"OK" –> SERVICE –> "OK" –> Service Code "8500".

Call up the dialog line "Tube" via "

6

" (DIALOG CENTER)

–> "OK" –> SERVICE –> "OK" –> Service Code "8500".

Call up the dialog line "Overscan" via "

6

" (DIALOG CENTER)

–> "OK" –> SERVICE –> "OK" –> Service Code "8500".

Call up the dialog line "NTSC 3.6" via "

6

" (DIALOG CENTER)

–> "OK" –> SERVICE –> "OK" –> Service Code "8500".

Feed in a grey scale black/white test pattern with burst.

Contrast (

W

) to maximum.

Colour contrast (

E

) to mid-position.

Screen brightness (

R

) to mid-position.

Call up dialog line "WHITE ADJUSTMENT" via "

6

" (DIALOG

CENTER) –> "OK" –> SERVICE –> "OK" –> Service Code

"8500".

Call up dialog line "Cut-off align" via "

6

" (DIALOG CENTER)

–> "OK" –> SERVICE –> "OK" –> Service Code "8500".

Feed in a convergency test pattern.

Contrast (

W

) to maximum.

Set the screen brightness (

R

) so that the black

background of the test pattern just starts to brighten.

Alignment

Preparations

Alignment Process