15

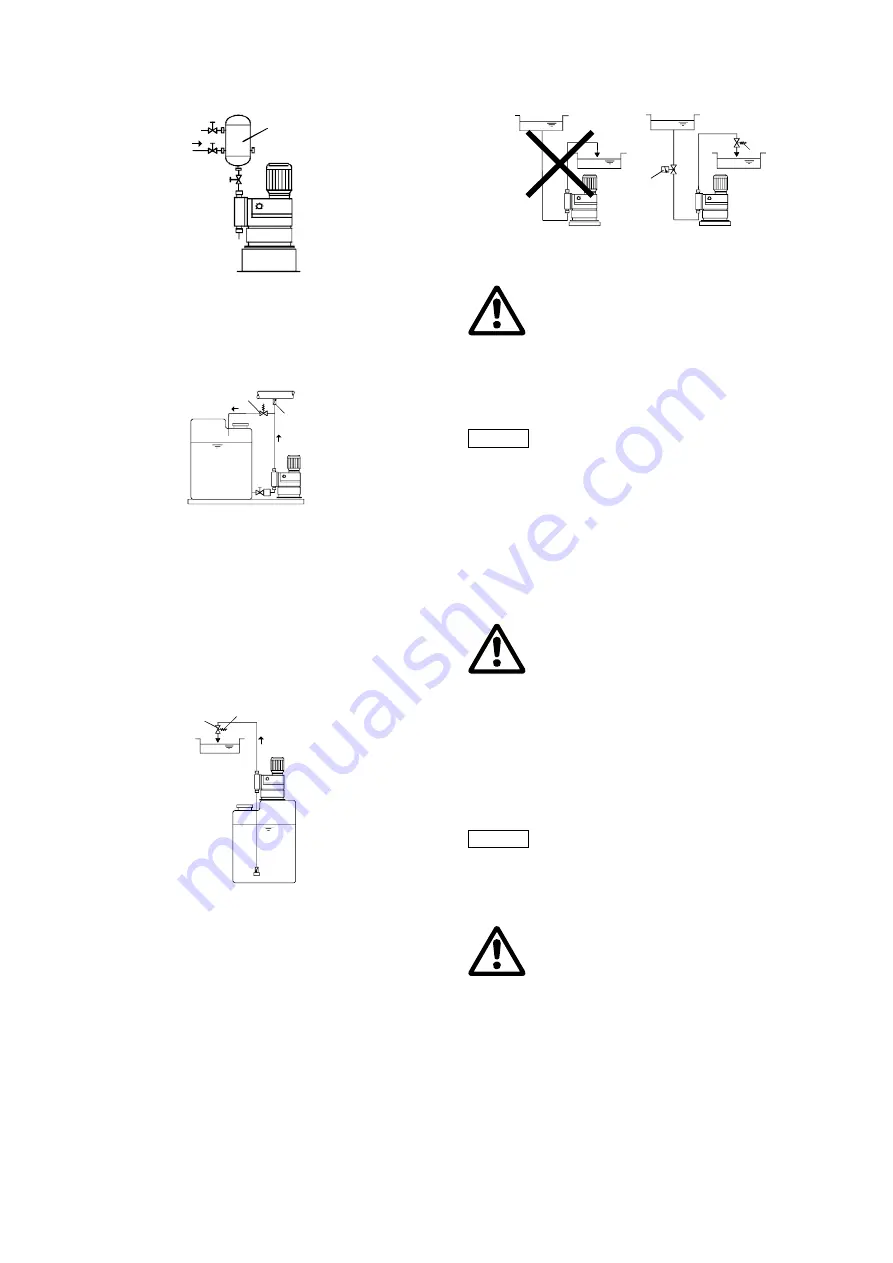

• Note for discharge-side installation: To protect the piping, use

a pulsation damper (8i) for rigid piping longer than 3 metres

and tubing longer than 5 metres.

Fig. 8

Installation with discharge-side pulsation damper

• For degassing and viscous media: flooded suction.

• To protect the dosing pump and the discharge line against

excessive pressure build-up, install a relief valve (6i) in the

discharge line.

Fig. 9

Installation with relief valve

With open outflow of the dosing medium or a counter-

pressure below 1 bar

• Install a pressure-loading valve (7i) immediately before the

outlet or the injection unit.

A positive pressure difference of at least 1 bar must be ensured

between the counter-pressure at the injection point and the

pressure of the dosing medium at the pump suction valve.

• If this cannot be ensured, install a pressure-loading valve (7i)

in the discharge line.

Fig. 10

Installation with pressure-loading valve

• To avoid the siphon effect, install a pressure-loading valve (7i)

in the discharge line and, if necessary, a solenoid valve (14i) in

the suction line.

Fig. 11

Installation to avoid the siphon effect

8.3 Mounting

• Mount the pump horizontally on the tank or on a console using

four M8 screws.

8.4 Tube / pipe lines

8.4.1 General

8.5 Connecting the suction and discharge lines

• Connect the suction line to the suction valve.

– Install the suction line in the tank so that the foot valve

remains 5 to 10 mm above the bottom of the tank or the

possible level of sedimentation.

• Connect the discharge line to the discharge valve.

T

M

03

6

3

01

45

06

T

M

03

63

02

45

06

TM

03

63

03

45

06

8i

6i

10i

p

7i

p

1 bar

p

≥

1 bar

TM

03

63

04

45

06

Warning

Risk of hot surfaces!

Pumps with AC motors may become hot.

Allow a minimum space of 100 mm to the fan

cover!

Caution

Gently tighten the screws in order not to damage

the plastic enclosure!

Warning

To protect the dosing pump against excessive

pressure build-up, install a relief valve in the

discharge line.

Only use the prescribed line types!

All lines must be free from strain!

Avoid loops and buckles in the tubes!

Keep the suction line as short as possible to

avoid cavitation!

If necessary, use swept bends instead of elbows.

Observe the chemical manufacturer's safety

instructions when handling chemicals!

Make sure that the pump is suitable for the actual

dosing medium!

The flow must run in the opposite direction to

gravity!

Caution

The resistance of the parts that come into contact

with the media depends on the media, media

temperature and operating pressure. Ensure that

parts in contact with the media are chemically

resistant to the dosing medium under operating

conditions!

Warning

All lines must be free from strain!

Only use the prescribed line types!

14i

p

1

p

2

2

p - p

1

1 bar

>

_

p

2

-p

1

≥

1 bar

Содержание DMX 115-3

Страница 1: ...DMX 221 GRUNDFOS ALLDOS INSTRUCTIONS Installation and operating instructions ...

Страница 29: ...29 ...

Страница 30: ...30 ...