5

Eng

lish (

U

S)

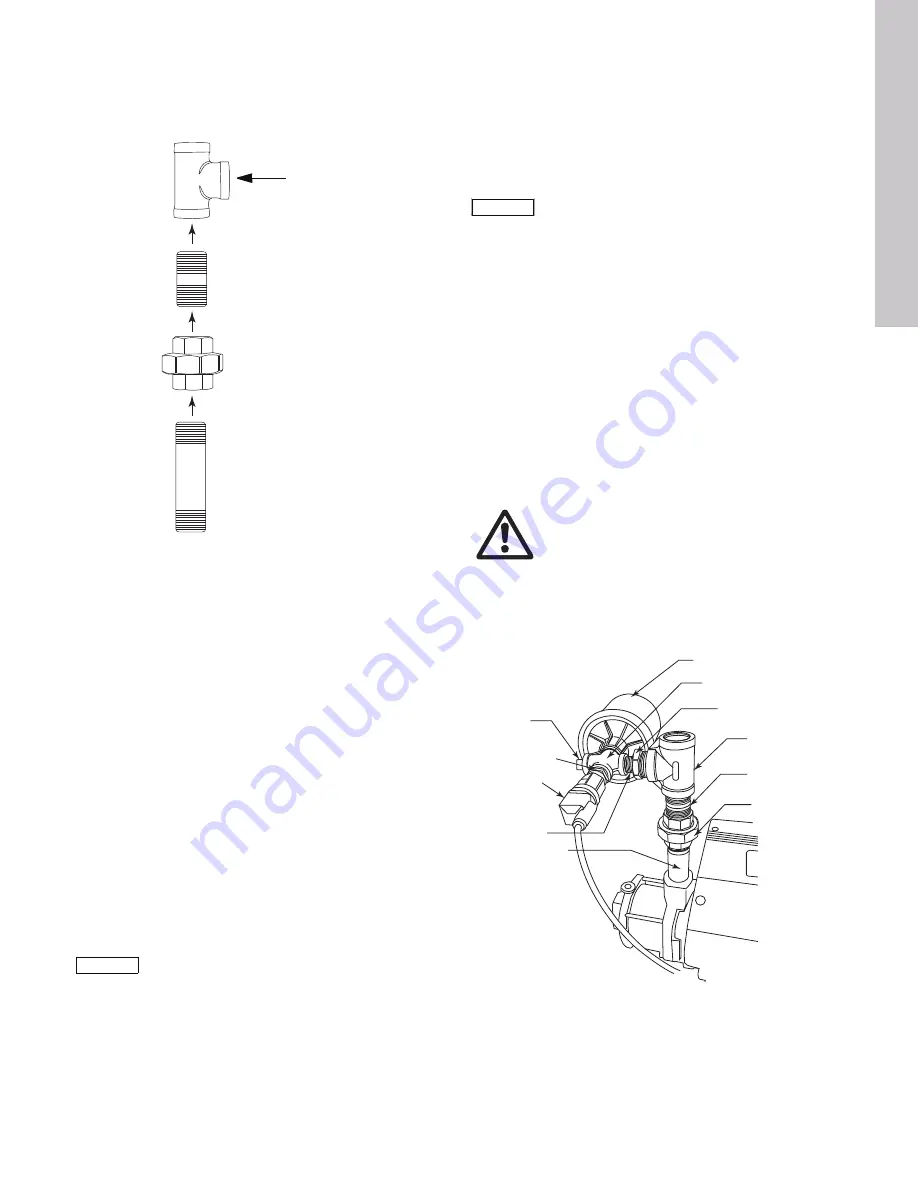

7. Thread the tank/transducer manifold assembly to discharge

tee as shown in fig. 7. Tighten wrench tight.

8. Tighten the cross fitting such that the transducer, plug and

bushing(s) are positioned horizontally. Tighten wrench tight.

Fig. 7

Threading tank/transducer manifold assembly to

discharge tee

5.3 Attach the tank

1. Remove the plastic protective cover from over the tank

threads. Confirm the O-ring is in place and thread the tank into

the final port in the 1/2” NPT cross fitting opposite the

pressure transducer. Tank should now also be horizontal.

Tighten until hand tight.

2. The tank is pre-charged from the factory to 50 psi (+/- 7 psi)

and may need to be adjusted for optimum pump performance.

Tank pre-charge pressure must be 0.7 x actual setpoint.

49 psi is the correct pre-charge setting for a 70 psi setpoint

(70 x 0.7 = 49).

6. Install the pump

1. Install the pump according to the CM and CME Installation and

Operating Instructions with these additional steps:

– Wrap 3 to 4 turns of Teflon tape on the male threads of the

suction size pipe nipple.

– Thread the suction sized pipe nipple directly in the pump

inlet fitting.

– Thread the check valve onto the pipe nipple; tighten until

wrench tight.

2. Connect the main power cable and pressure transducer cable

to the motor terminal box according to the CME Installation

and Operating Instructions supplied with the pump.

6.1 Set the pump parameters

Using an R100 remote programmer, set the following parameters:

• SENSOR TYPE: As per the label on the transducer (typically

4-20 mA and range 0-87 psi (0-6 bar) or 0-145 psi (0-10 bar))

• STOP FUNCTION:Active

• CONTROL MODE:Controlled

6.2 Perform functional test

Start the pump and perform the following functional test including

monitoring for leaks and watching for any obvious problems:

1. Reduce the setpoint to the second LED light from the bottom

on the motor control panel by pressing the DOWN arrow as

many times as necessary.

2. Slowly close the discharge line valve and observe that the

motor reduces speed to compensate for the lower flow rate.

3. Fully close the discharge line valve to test the motor stop

function. (The motor should stop within approximately

2 minutes if there are no leaks).

Note: The stop function may not operate properly, if the

setpoint requires 90% to 100% of the motor maximum speed

or if the diaphragm tank pre-pressure is not in the desired

range

.

4. Fully open the discharge line valve and observe that the pump

starts again.

5. The pump is ready for its normal operation now. Please see

the CME Installation and Operating Instructions supplied with

the pump for further instructions.

Fig. 8

Completed kit assembly

T

M

05 06

52 13

11

Note

Note

If you purchased a complete CME-Plus from

the factory, the pressure transducer and R100

settings are already installed

.

Thread tank/transducer

manifold assembly here

Note

Note

Pump must be primed before functional test.

Warning

After setting your pump setpoint, be sure that

you have not inadvertently set the pump to run on

Max Curve

,

Min Curve

or

Stop

. See the CRE,

CRIE...CME Installation and Operating

Instructions for more information.

T

M

05 0

659 1

41

1

Tank with O-ring

1/2" NPT cross fitting

1/2" to discharge

size bushing

Discharge

tee

1/2" NPT

plug

1/4" to 1/2"

NPT bushing

Transducer

1/2" NPT

pipe nipple

Discharge

nipple

Discharge

union

Discharge

pipe

CME Plus Kit Assembly I&O.book Page 5 Thursday, April 7, 2011 4:41 PM

Содержание CME-Plus

Страница 1: ...GRUNDFOS INSTRUCTIONS CME Plus Kit assembly Installation and operating instructions ...

Страница 2: ...2 ...

Страница 6: ...6 ...