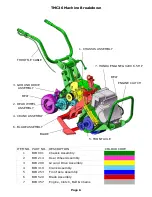

Blade Assembly

The cutter blades are attached to the blade drive leg by a unique three bolt tri-pad mounting

system which enables the operator to adjust the blade to get an equal thickness across the

width of the cut before finally tightening the blade mounting bolts. The tri-pad mounting

system can also accommodate a variety of blades and attachments. All blades are made

from hardened toughened steel and the sod undercutting blades have an arched cross

section allowing the sod to flow easier over the blade while stiffening the blade to prevent

sagging thereby maintaining thickness across the width of the sod..

The upper end of the blade drive leg clamps onto a sealed bearing spindle contained within a

pivoting-arm and depth lever bracket which enables the blade to be raised and lowered to

set the cutting depth or to raise the blade out of work. The selected cutting depth is locked

securely by two clamp plungers and a locking lever. The blade cutting angle remains

constant at all depths. The cutting angle can be altered by loosening the four jockey-wheel

mounting bracket bolts at the rear of the machine and sliding the jockey wheel bracket up or

down on the slots tilting the chassis and changing the blade cutting angle as indicated by the

pointer and scale beside the bracket.

Rear Wheel Assembly

The pneumatic caster tail wheel is mounted on a bracket attached to the rear of the chassis

by four bolts. A foot lever enables the caster wheel to be locked or allowed to swivel for

straight line or curve cutting. For loading, transportation and storage, the caster wheel

should be locked forward facing the chassis. For cutting the caster wheel should be

positioned facing backwards away from the chassis. The caster wheel mounting bracket can

be adjusted up or down to tilt the chassis altering the blade cutting angle as described in the

Blade Assembly paragraph above.

Chassis Assembly

An engine guard is incorporated at the front of chassis. The chassis is designed to allow

access to the mechanisms with the minimum of dismantling. The main sub assemblies can

be removed independently if repairs or maintenance is required. The belt drives are located

external of the chassis and easily accessed by removing the belt covers. The operator

handles are mounted to the chassis by four double jointed circular rubber mounts. These are

positioned and mounted so as to allow maximum deflexion on a vertical plane to absorb

cutting vibrations in work while restricting the right / left or lateral movement for maximum

operator control to steer and guide the machine in the cut. A limit stop is incorporated to

prevent damage to the rubber joints if excessive force is applied the operator handles. The

handles can be folded over the chassis for compact storage.

SEE TMC26 PARTS MANUAL FOR EXPLODED PARTS ILLUSTRATIONS AND PART NUMBERS

TMC26 Technical Information

Page 8

Содержание TMC24 TURF multi Cutter

Страница 21: ...Page 18 NOTES www groundsmanindustries com ...