OM-TDB/7

13

The pressure gauge should show a vacuum

of 20 to 30 inches when the kettle is cold.

Maintenance

NOTICE: Contact Groen or an authorized Groen representative when repairs are required.

1.

Periodic Maintenance

A Maintenance & Service Log is provided at

the back of this manual with the warranty

information. Each time maintenance is

performed on your Groen kettle, enter the

date on which the work was done, what was

done, and who did it. Keep this manual on

file and available for operators to use.

Periodic inspection will minimize equipment

down time and increase the efficiency of

operation. The following points should be

checked:

[BY OPERATOR]

a.

Check the pressure/vacuum gauge every

day. The gauge should show a vacuum

of 20 to 30 inches, when the kettle is

cold. If it does not, see “Jacket Vacuum”

on page 10.

b.

Also check the jacket water level on a

daily basis. It should be above mid point

of round sight glass (new models) or

between the marks on the gauge glass

(old models). If the level is low, see

“Jacket Filling and Water Treatment” on

page 14.

[BY SERVICE TECHNICIAN]

c.

Electrical wiring should be kept securely

connected and in good condition.

d.

The inside of the support housing should

be kept clean.

Test the safety valve at least twice each

month. Test the valve with the kettle

operating at 15 psi (105 kPa), by holding the

test lever for at least 5 seconds. Then

release the lever and let the valve snap shut.

If the lever does not activate, or there is no

evidence of discharge, or the valve leaks,

immediately discontinue use of the kettle and

contact a qualified Groen service

representative.

WARNING

WHEN TESTING, AVOID ANY EXPOSURE

TO THE STEAM BLOWING OUT OF THE

S AF E T Y VALVE. DIRECT CONT AC T

COULD RESULT IN SEVERE BURNS.

DISCONNECT ELECTRICAL POWER FROM

THE KETTLE BEFORE ATTEMPTING TO

GREASE THE TRUNNION BEARINGS.

At least twice a year, grease the two

trunnion bearings. The bearings are located

within the kettle support housing. Remove

the access panels from the support housing

with a screwdriver to gain access to the

grease fittings. Use a lithium-based, multi-

purpose grease. When the access panels

are removed, the mounting bolts for the

trunnion bearings and tilt switch can also be

checked for tightness. When finished,

reassemble access panels to support

housing.

2.

Jacket Vacuum

When the kettle is cold, a positive pressure

reading or a reading around zero on the

pressure/vacuum gauge indicates the

presence of air in the jacket. Air in the jacket

slows down the heating of the kettle.

To remove air:

a.

Start the unit. (See the “Operation”

section of this manual.) (Be sure there is

water or product in the kettle when

heating).

b.

When the pressure/vacuum gauge

reaches a positive pressure reading of 5

PSI, release the trapped air and steam

by pulling up or out on the safety valve

Содержание OM-TDB/7

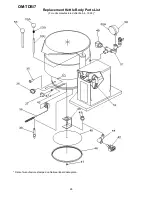

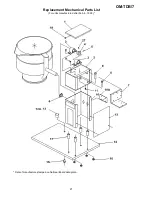

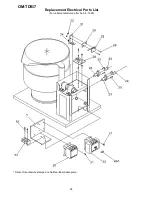

Страница 15: ...OM TDB 7 15 ...

Страница 21: ...OM TDB 7 21 For units manufactured before September 1 1998 ...

Страница 23: ...OM TDB 7 23 For units manufactured between September 1 1988 and July 1 1992 ...

Страница 25: ...OM TDB 7 25 For units manufactured between July 1 1992 and February 6 1995 ...

Страница 30: ...OM TDB 7 30 Wiring Diagrams For units manufactured before September 1 1988 ...

Страница 31: ...OM TDB 7 31 Wiring Diagrams For units manufactured before September 1 1988 ...

Страница 32: ...OM TDB 7 32 Wiring Diagrams For units manufactured before September 1 1988 ...

Страница 33: ...OM TDB 7 33 Wiring Diagrams For units manufactured after September 1 1988 and before June 1 1990 ...

Страница 34: ...OM TDB 7 34 Wiring Diagrams For units manufactured after September 1 1988 and before June 1 1990 ...

Страница 35: ...OM TDB 7 35 Wiring Diagrams For units manufactured after September 1 1988 and before June 1 1990 ...

Страница 36: ...OM TDB 7 36 Wiring Diagrams For units manufactured after June 1 1990 and before July 1 1992 ...

Страница 37: ...OM TDB 7 37 Wiring Diagrams For units manufactured after June 1 1990 and before February 6 1995 ...

Страница 38: ...OM TDB 7 38 Wiring Diagrams For units manufactured after July 1 1992 and before February 6 1995 ...

Страница 41: ...41 OM TDB 7 TDB 7 20 TDB 7 40 480 VOLT 1 3 PHASE Wiring Diagrams For units manufactured after Feb 6 1995 ...