Model T32713 (Mfd. Since 08/21)

-3-

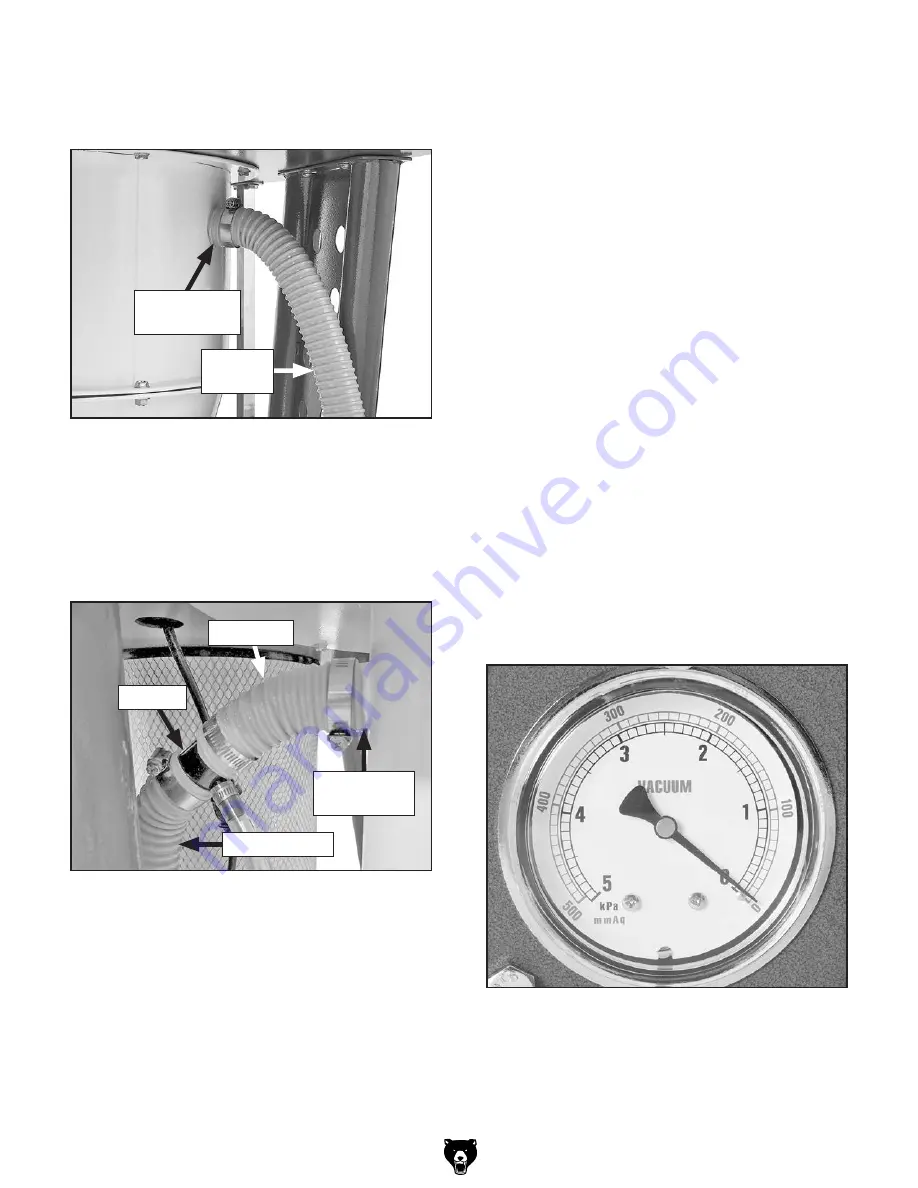

7. Loosen hose clamp securing vacuum hose to

intake barrel port and remove hose from port

(see

Figure 7).

8. Slide other end of dust hose from Step 4 over

intake barrel port (see

Figure 8).

9. Slide vacuum hose over other port on T-fitting

(see

Figure 8).

10. Adjust and orient hoses and clear tube as

needed to eliminate any kinks, then tighten

all (5) hose clamps to secure connections.

11. Slide pressure gauge mount to position where

it is easy to read, and secure in place with (2)

flange nuts removed in

Step 5.

12. Connect dust collector to power.

Figure 7. Vacuum hose attached to intake barrel

port.

Vacuum

Hose

Intake Barrel

Port

Figure 8. Dust hose placed over intake barrel

port and vacuum hose over T-fitting port.

13. Cover intake dust ports and turn dust collec-

tor

ON. Pressure gauge should indicate at

least 200mmAq or 2kPa.

— If gauge indicates at least 200mmAq or

2kPa, negative pressure kit has been

installed correctly and filter is operating

efficiently.

— If gauge indicates less than 200mmAq

or 2kPa, confirm all hose and tube con-

nections are tight and there are no kinks

that disrupt air flow. If gauge still indicates

less than 200mmAq, refer to

Reading

Pressure Gauge to service filter as

required.

Reading Pressure Gauge

The Model G0860, G0861, and G0862 use a

handle and internal paddles to remove the dust

buildup from the filter. The negative pressure

gauge will help determine when a more thorough

cleaning is needed and whether the filter should

be replaced.

If the operating pressure on the pressure gauge

drops below 200mmAq or 2kPa (see

Figure 9),

remove and clean the filter, as described in the

Owner's Manual.

If the operating pressure drops below 150mmAq

or 1.5kPa, and cleaning does not improve perfor-

mance, replace the filter.

Figure 9. Pressure gauge values.

Dust Hose

T-Fitting

Intake Barrel

Port

Vacuum Hose