Shop Fox

®

Classic Fence

-13-

3.

Centralize the magnified cursor within

its range of adjustment and tighten the

screws. Mark the position of the hairline on

the front rail tube with a pencil. This is the

zero mark for applying the scale.

4.

Remove the fence and apply a strip of

masking tape along the rail a

1

⁄

2

'' in from

the front edge.

5.

Using the zero mark as the starting point

and the masking tape as a guide, apply the

adhesive scale to the rail.

See Figure 13.

Push the scale into place with heavy thumb

pressure.

Be careful when laying the scale into position

because the scale can be stretched if too

much pressure is applied.

Figure 12.

Fence contacting the blade.

Figure 13.

Scale location for right-side blade use.

Approx 5

7

⁄

8

''

Zero Point for

right of blade use

Scale

1

⁄

2

'' From Front Edge

Figure 14.

Scale location for right-side blade use.

Approx 5

7

⁄

8

''

Zero Point for

left of blade use

Scale

1

⁄

2

'' From Front Edge

6.

To fine tune the position of the magnified

cursor, make a test cut and adjust the

cursor to correspond with the actual width

of the test board. This method accounts

for any vibration or wobble that may be

present in the spinning blade.

Different blades may have different widths

of cutting teeth, so readjustment is required

whenever changing type or style of blade. This

procedure must be repeated every time the saw

blade is changed to maintain accuracy.

When cutting on the left side of the blade,

this scale will not be accurate. It is possible to

attach another scale (not included) which can

be set for left side cutting.

See Figure 14

. The

magnified cursor assembly can be moved to the

left side of the fence to allow for orienting a

separate scale.

Scale and Cursor

The self adhesive scale and magnified cursor

provide fast and accurate fence positioning.

1.

Loosen the adjusting screws on the

magnified cursor until the cursor can be

adjusted.

2.

Raise the table saw blade guard out of the

way. With the fence mounted on the right

side of the blade, slide it over until its left

edge touches the side of the blade.

See

Figure 12.

Содержание H6472

Страница 3: ......

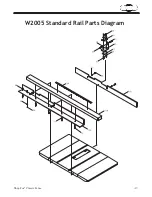

Страница 20: ...Shop Fox Classic Fence 17 26 W2005 Standard Rail Parts Diagram ...

Страница 23: ......

Страница 24: ......

Страница 25: ......