-18-

g8749 drum/Flap sander

SEctiON 6: MAiNtENANcE

Always disconnect power

to the machine before

performing maintenance.

Failure to do this may

result in serious person-

al injury.

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily check:

•

loose mounting bolts.

•

damaged or worn sandpaper/brushes.

•

sanding drum air pressure.

•

Worn or damaged wires.

•

any other unsafe condition.

Daily Maintenance:

•

Clean machine.

Schedule

Cleaning the Model g8749 is relatively easy.

Vacuum excess wood chips and sawdust, and

wipe off the remaining dust with a dry cloth. if any

resin has built up, use a resin dissolving cleaner

to remove it.

cleaning

Lubrication

Bearings are sealed and permanently lubricated,

so simply leave them alone unless they need

replacement.

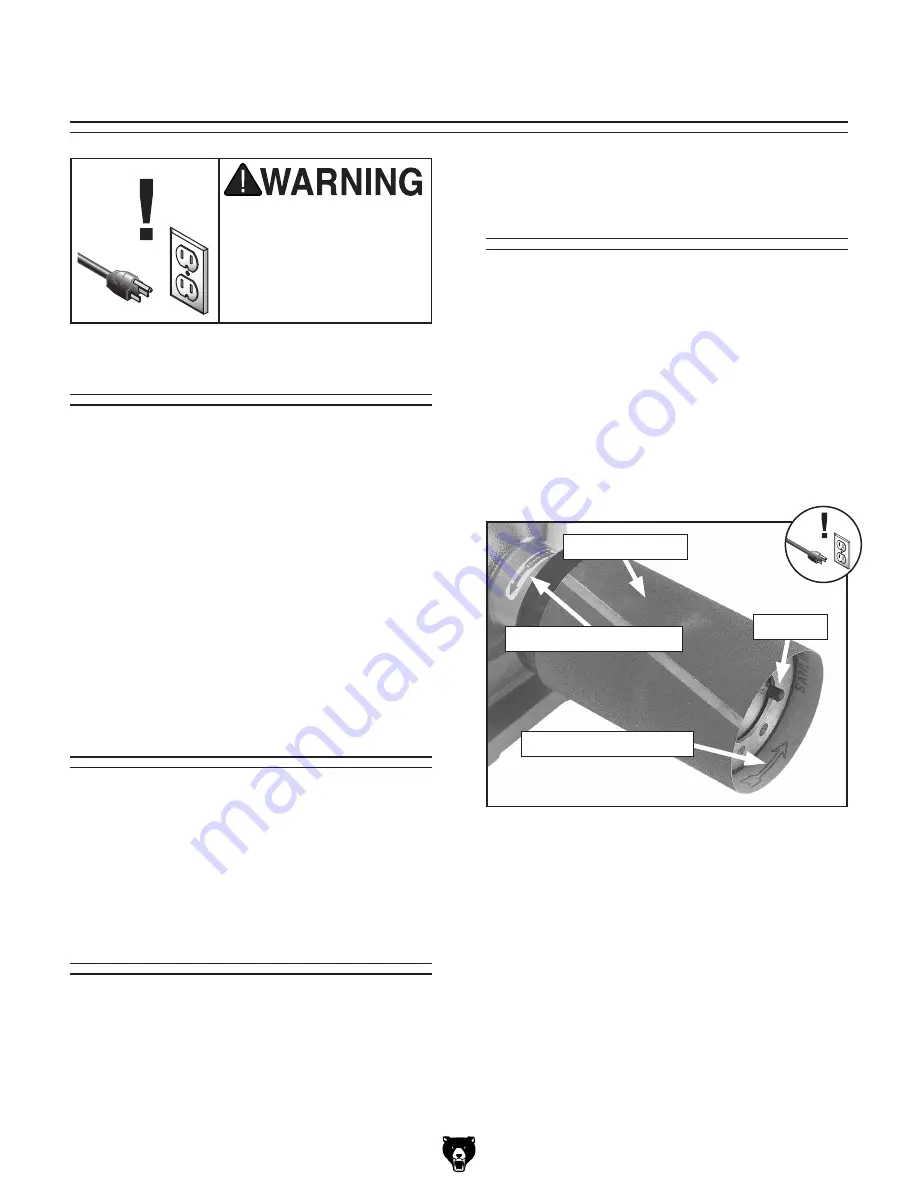

Replacing Sanding

Sleeves

your sander is supplied with a large 4

3

⁄

4

" x 8"

sanding drum and a smaller 3

1

⁄

4

" x 8" drum. Both

drums will accept soft or hard sanding sleeves.

to replace the sanding sleeve:

1. disConnECt sandEr FroM poWEr!

2. remove the air valve protective cap, press

the valve stem to release the drum air pres-

sure (see

Figure 20), then slide the sleeve off

the drum.

Figure 20. replacing sanding sleeve.

air Valve

spindle rotation arrow

sleeve rotation arrow

3. Match the direction of the sleeve rotation

arrow with the spindle rotation arrow, then

slide the replacement sleeve onto the drum.

Note:

Make sure the sanding sleeve does not

extend beyond either end of the drum.

4. use a hand-operated air pump to inflate the

sanding drum to 10 psi, then replace the

valve cap.

sanding sleeve

Содержание G8749

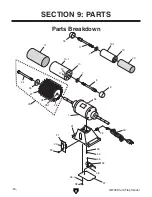

Страница 26: ...24 G8749 Drum Flap Sander 6 Parts Breakdown SECTION 9 PARTS...

Страница 28: ...26 G8749 Drum Flap Sander...