-12-

g8749 drum/Flap sander

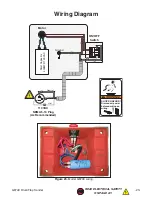

5. turn the machine

OFF

.

6. remove the switch disabling key, as shown

in

Figure 9.

7. try to start the machine by flipping the paddle

switch up to the on position.

—if the machine does not start, the switch

disabling feature is working as designed.

—if the machine starts, immediately stop it.

the switch disabling feature is not working

correctly. this safety feature must work

properly before proceeding with regular

operations. Call tech support for help.

Figure 9. removing switch key from paddle

switch.

Assembly

the flap sander is designed to be mounted only

on the left side of the machine, whereas the drum

sanders can be mounted on either side.

Attaching Flap Sander

1. disConnECt sandEr FroM poWEr!

2. When removed from the shipping box, the

flap sander is held together by two tie wraps.

hold the assembly together from top to bot-

tom, then remove the ties and store them for

future use.

Note:

If the brushes should come loose

from the end plates during this step, refer

to

Replacing Flap Sandpaper/Brushes on

Page 19 for detailed instructions on how to

put the assembly back together.

3. position the flap sander so the sanding sur-

face of the paper is facing you, then carefully

slide it onto the left hand arbor, as shown in

Figure 10.

Figure 10. installing flap sander.

4. secure the flap sander by threading the flap

sander arbor bolt and flange into the spindle,

as shown in

Figure 10. Make sure to fully

tighten the bolt.

Note:

This arbor bolt has left-hand threads

and tightens by rotating it counterclockwise.

Содержание G8749

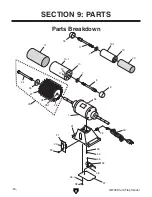

Страница 26: ...24 G8749 Drum Flap Sander 6 Parts Breakdown SECTION 9 PARTS...

Страница 28: ...26 G8749 Drum Flap Sander...