G1495 Heavy-Duty Wood Lathe

-11-

Pre-assembly

Assembly of the G1495 is straightforward. We

have organized the assembly process into steps.

Please follow them in sequence.

Tools Required: Only a few common tools are

needed to assemble this machine. Specifically,

two 12mm open end wrenches, a 6mm Allen

®

wrench (supplied), a Phillips

®

screwdriver and a

plumb bob.

SECTION 4: ASSEMBLY

Stand

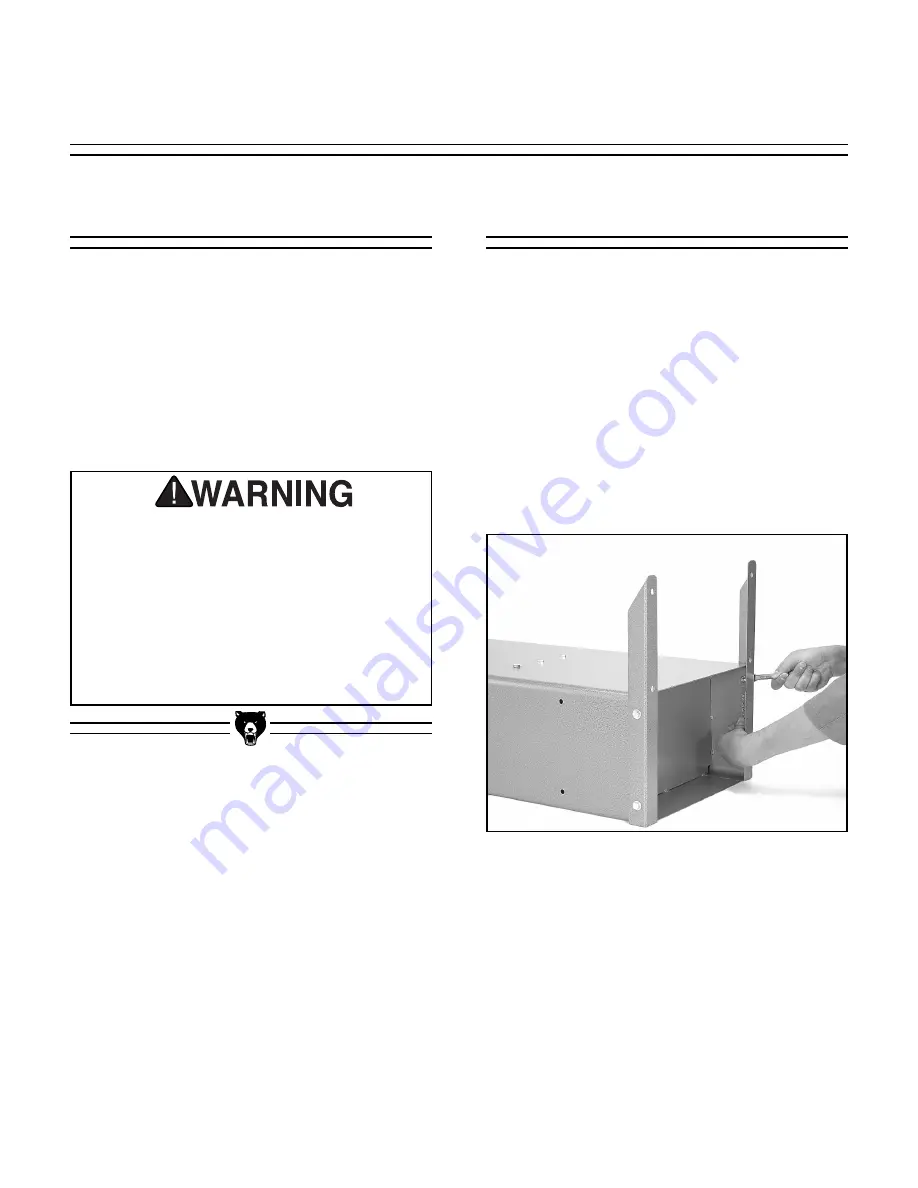

Figure 4. Attaching base brackets to stand.

(Stand is lying down on its front)

The stand components are most easily assem-

bled on their sides, then stood up and joined

together:

1. Attach the two base brackets to the base of

the cabinet using four (4)

5

⁄

16

'' - 18 x

3

⁄

4

'' bolts

and nuts. Use two (2) washers for each bolt,

one under the head of the bolt, one next to

the nut. These brackets are used when the

lathe is going to be bolted to the floor or

other type of support structure. See Figure

4.

All die-cut metal parts have a sharp edge

(called “flashing”) on them after they are

formed. This is generally removed at the fac-

tory. Sometimes a bit of flashing might

escape inspection, and the sharp edge may

cause cuts or lacerations when handled.

Please examine the edges of all die-cut

metal parts and file or sand the edge to

remove the flashing before handling.

2. Attach the third base bracket to the right

hand stand using two (2)

5

⁄

16

'' - 18 x

3

⁄

4

''

bolts, washers and nuts.