Model G1163/G1163P (Mfg. Since 9/12)

-11-

voltage Conversion to 240v

the voltage conversion MuSt be performed by

an electrician or qualified service personnel. to

perform the voltage conversion, install the cor-

rect plug and rewire the motor to the new voltage,

according to the provided wiring diagram. If the

diagram included on the motor conflicts with the

one on

Page 24 in this manual, the motor may

have changed since the manual was printed. Use

the diagram provided inside the motor wiring junc-

tion box.

Items Needed

Qty

•

phillips head Screwdriver #2 ..................... 1

•

Electrical tape ............................ as Needed

•

Wire Nut (16 aWG x 3) ............................... 1

•

6-15 plug .................................................... 1

To convert the Model G1163/G1163p to 240v:

1. DiSCoNNECt MaChiNE FRoM poWER!

2. open the motor junction box, then loosen the

wire nuts indicated in

figure 4.

3. use wire nuts to connect the wires as indicat-

ed in

figure 5. twist all three wire nuts onto

their respective wires and wrap them with

electrical tape so they will not come loose.

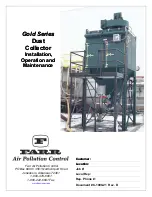

120 Volt Motor

Ground

Paddle

Switch

Neutral

Hot

Ground

120 VAC

240 VAC

5-15 Plug

240 Volt Motor

Paddle

Switch

Hot

Hot

Ground

6-15 Plug

(As Recommended)

240

VAC

Ground

Wt

Wt

Start

Capacitor

200MFD

125VAC

Run

Capacitor

30MFD

250VAC

Start

Capacitor

200MFD

125VAC

Run

Capacitor

30MFD

250VAC

G

figure 4. location of wire nuts to be loosened

on when converting voltage.

loosen

these

Wire Nuts

4. Close and secure the motor junction box.

5. Remove the 5-15 plug from the power cord

and install a 6-15 plug according to the manu-

facturer's instructions.

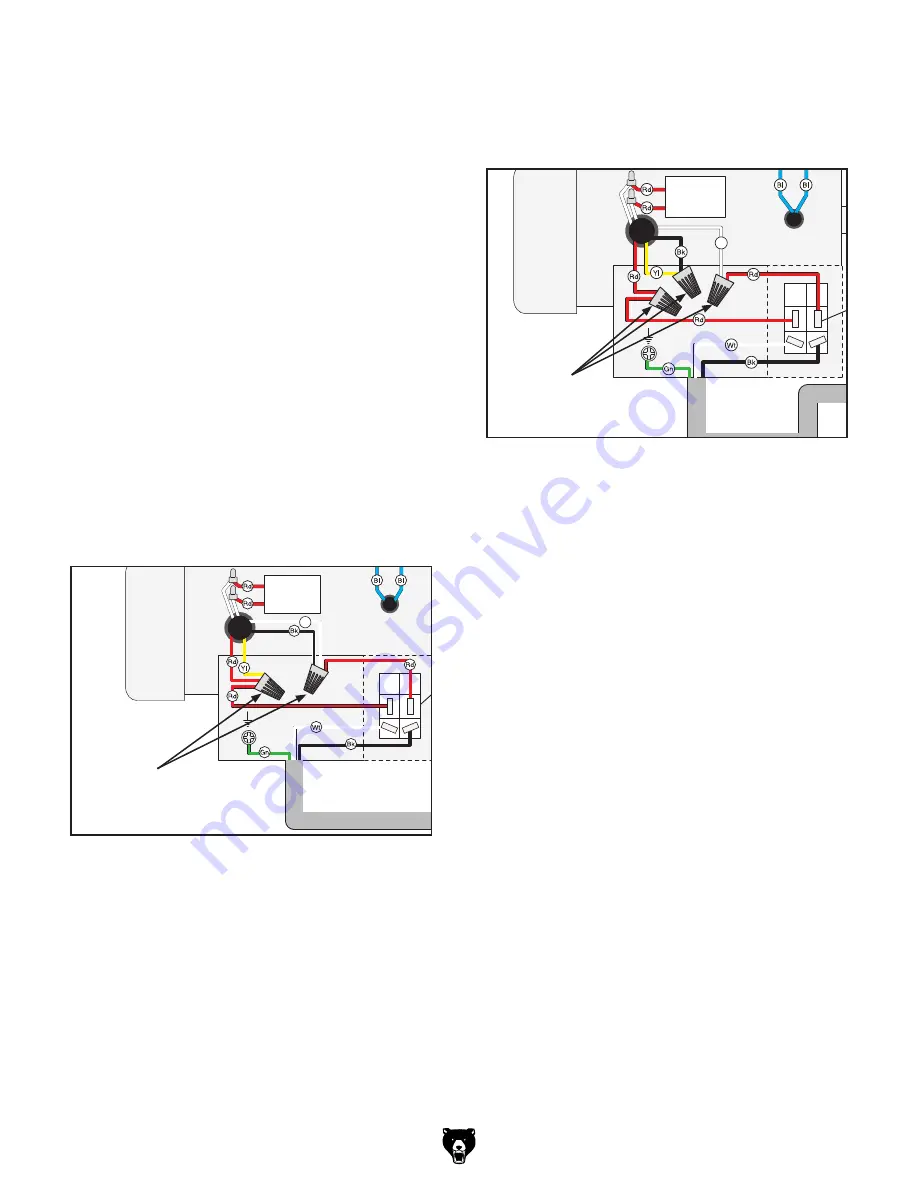

120 Volt Motor

Ground

Paddle

Switch

Neutral

Hot

Ground

120 VAC

240 VAC

5-15 Plug

240 Volt Motor

Paddle

Switch

Hot

Hot

Ground

6-15 Plug

(As Recommended)

240

VAC

Ground

Wt

Wt

Start

Capacitor

200MFD

125VAC

Run

Capacitor

30MFD

250VAC

Start

Capacitor

200MFD

125VAC

Run

Capacitor

30MFD

250VAC

G

figure 5. Model G1163/G1163p rewired to

240v.

Connect

Wires with

Nuts here

Содержание G1163

Страница 32: ......