Model G0745 (Mfg. Since 11/13)

-21-

to ensure accurate work, it is extremely important

that the spindle nose and chuck mating surfaces

remain clean during installation. Even a small

amount of dirt or debris can affect accuracy.

the chuck is properly installed when it threads

all the way onto the spindle nose (see

figure 16)

and evenly seated against the spindle shoulder.

Tools Needed:

Qty

Chuck Keys ....................................................... 2

spindle Key ....................................................... 1

Chuck Installation

1. disCoNNECt lathE FroM poWEr!

2. use an appropriate device to protect the

ways during the installation process (refer

to

Installation & Removal Device on page

20).

3. thoroughly clean, inspect, deburr, and lightly

oil all threads and mating surfaces.

4. thread the chuck onto the spindle nose and

hand-tighten it.

5. remove the cap screw that secures the end

cover, then open the end cover.

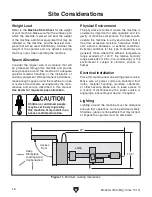

figure 16. spindle nose (M14-1.0 threads).

threads

spindle

shoulder

6. insert the spindle key and chuck key, as

shown in

figure 17, and tighten the chuck

snug against the spindle shoulder.

figure 17. tightening chuck onto spindle with

spindle and chuck keys.

7. Close and secure the end cover.

spindle Key

Chuck Key

Chuck Removal

1. disCoNNECt lathE FroM poWEr!

2. use an appropriate device to protect the ways

(refer to

Installation & Removal Device on

page 20).

3. remove the cap screw that secures the end

cover, then open the end cover.

4. use the spindle key and chuck key, as shown

in

figure 17, to loosen and remove the

chuck.

Chuck Installation &

Removal

Содержание G0745

Страница 44: ... 42 Model G0745 Mfg Since 11 13 Figure 47 Circuit board ...

Страница 52: ......