Содержание GRTFC83

Страница 10: ...10 DESCRIPTION GRTFR83 L TOOL PARTS 1 2 3 8 6 7 11 10 9 5 4 All manuals and user guides at all guides com ...

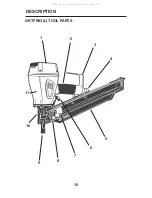

Страница 12: ...12 DESCRIPTION GRTFC83 TOOL PARTS 1 2 3 7 5 6 10 9 8 4 GRTFC83 All manuals and user guides at all guides com ...

Страница 14: ...14 DESCRIPTION GRTFW83 TOOL PARTS 1 2 3 7 5 6 10 9 8 4 GRTFW83 All manuals and user guides at all guides com ...

Страница 20: ...GRTFR83 PARTS SCHEMATIC 20 All manuals and user guides at all guides com ...

Страница 22: ...22 GRTFR83L PARTS SCHEMATIC All manuals and user guides at all guides com ...

Страница 24: ...24 GRTFC83 PARTS SCHEMATIC All manuals and user guides at all guides com ...

Страница 26: ...26 GRTFW83 PARTS SCHEMATIC All manuals and user guides at all guides com a l l g u i d e s c o m ...