Service Manual

41

Installation and Maintenance

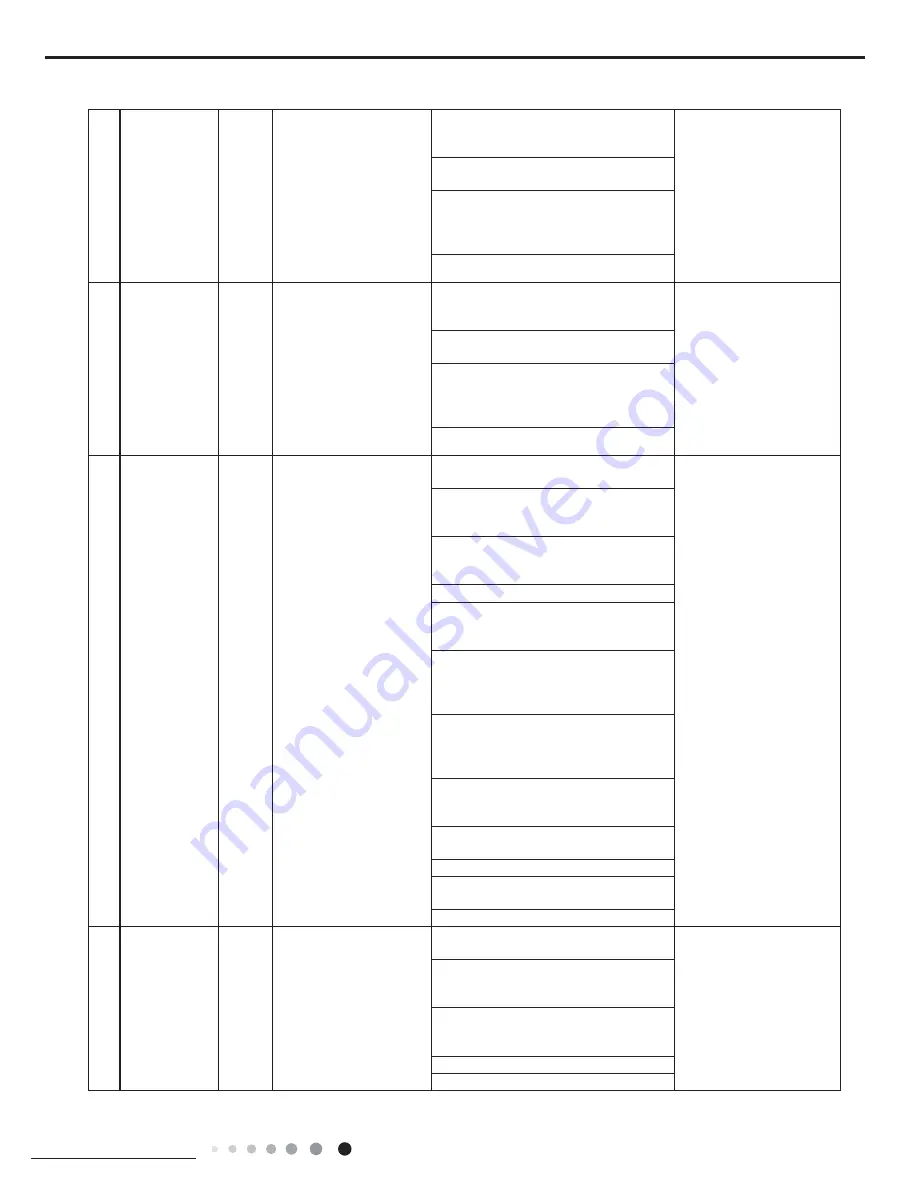

4

Outdoor

condenser

temperature

sensor is open/

short-circuited

F4

The unit will stop

operation as it reaches

the temperature point.

During cooling and drying

operation, the compressor

stops operation while IDU

fan motor operates; During

heating operation, the

heating fan motor operates

according to the conditions

of blowing residual heat.

1. The wiring terminal between outdoor

condenser temperature sensor and

maiboard is loosened or poorly contacted;

Refer to Malfunction

Detection Flowchart

2. There’s short circuit due to trip-over of

the parts on maiboard;

3. Outdoor condenser temperature sensor

is damaged (Please check it by referring

to the resistance table for temperature

sensor);

4. Mainboard is broken.

5

Outdoor

discharge

temperature

sensor is open/

short-circuited

F5

The unit will stop

operation as it reaches

the temperature point.

During cooling and drying

operation, the compressor

stops operation while IDU

fan motor operates; During

heating operation, the

heating fan motor operates

according to the conditions

of blowing residual heat.

1. The wiring terminal between outdoor

discharge temperature sensor and

maiboard is loosened or poorly contacted;

Refer to Malfunction

Detection Flowchart

2. There’s short circuit due to trip-over of

the parts on maiboard;

3. Outdoor discharge temperature sensor

is damaged (Please check it by referring

to the resistance table for temperature

sensor);

4. Mainboard is broken.

6

High pressure

protection

E1

During cooling and drying

operation, except IDU

fan motor operates, all

loads stop operation.

During heating operation,

the complete unit stops

and operation of remote

controller or buttons is

unavailable.

1. The mainboard and the display board

are not connected well;

Refer to Malfunction

Detection Flowchart

2. The OVC terminal on mainboard is not

connected well with the high pressure

switch on the complete unit;

3. The wiring terminal between high

pressure switch and maiboard is loosened

or the high pressure switch is broken;

4. Refrigerant is superabundant;

5. Poor heat exchange (including blocked

heat exchanger and bad radiating

environment );

6. Ambient temperature is too high; (if it is

3-phase unit, the high pressure protection

may be caused by overcurrent protection

due to this reason);

7. The supply voltage is abnormal (if it is

3-phase unit, the high pressure protection

may be caused by overcurrent protection

due to this reason);

8. The air intake and air discharge at

indoor / outdoor heat exchanger are not

smooth;

9. Filter and heat exchange fins of indoor/

outdoor units are blocked;

10. The pipeline is blocked;

11. The gas valve and liquid valve for

outdoor unit are not completely opened;

12. The OVC input is at high level.

7

Low pressure

protection of

compressor

E3

The complete unit stops.

1.The mainboard and display board are

not connected well;

Refer to Malfunction

Detection Flowchart

2. The LPP terminal on the mainboard is

not connected well with the high pressure

switch;

3. The wiring of high pressure switch

is loosened or high pressure switch is

damaged.

4. The refrigerant is insufficient;

5. The LPP input is at high level.