❏

12. Attach the clevises to the aileron control horns. Press

the forks of the clevises together until the pin snaps into the

opposite fork. Slide the clevis retainer into position over

the clevis forks.

❏ ❏

13. Hold an aileron in its neutral position, and mark the

pushrod wire where it crosses the outer hole on the servo

arm using a felt-tip pen.

❏ ❏

14. Cut off the aileron pushrod approximately 3/8" [10mm]

past the mark.

❏ ❏

15. Make a 90º “L” bend at the mark that crosses the

servo arm.

❏ ❏

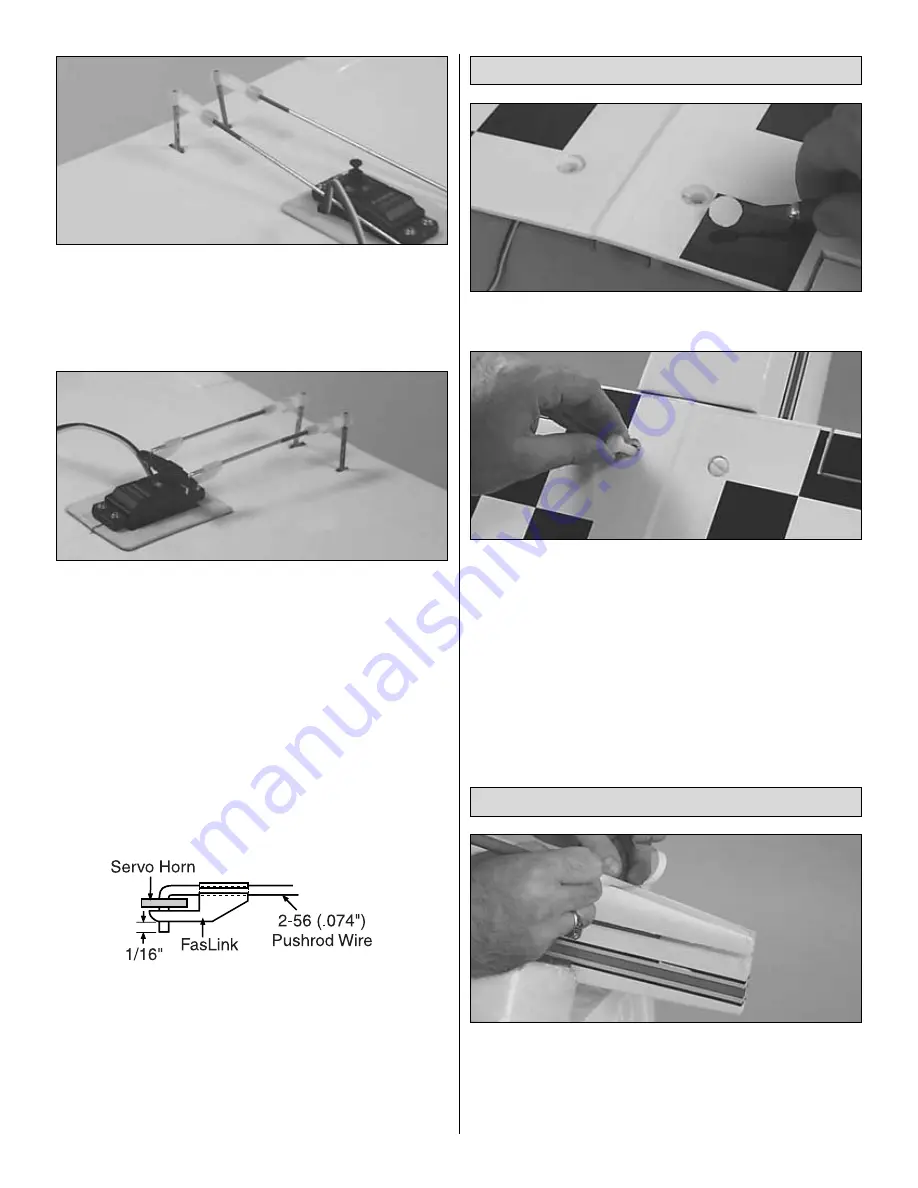

16. Attach the rod to the servo arm. Use a plastic FasLink

to secure the wire to the servo arm. You may need to

enlarge the holes in the servo arms slightly to allow the wire

to pass through the arm. (The Hobbico Quick Drill

™

set

HCAR0699 works well for this purpose.)

❏

17. Repeat steps 13 to 16 for the opposite aileron.

❏

1. Locate the holes for the wing bolts and remove the covering

from the top and bottom of the wing using a sharp hobby knife.

❏

2. Attach the wing to the fuselage using two 1/4-20 x 2"

nylon wing bolts.

❏

1. Locate the slot for the horizontal stabilizer and vertical fin

under the covering on the tail section of the fuselage by

gently pressing the covering with your finger. The elevator

slot is located on both sides of the fuselage. Using a sharp

hobby knife, carefully remove the covering, exposing the

slots.

Note: Do not cut into the wood around the slot.

Tail Installation

Wing Installation

8