7

13mm-14mm

❏

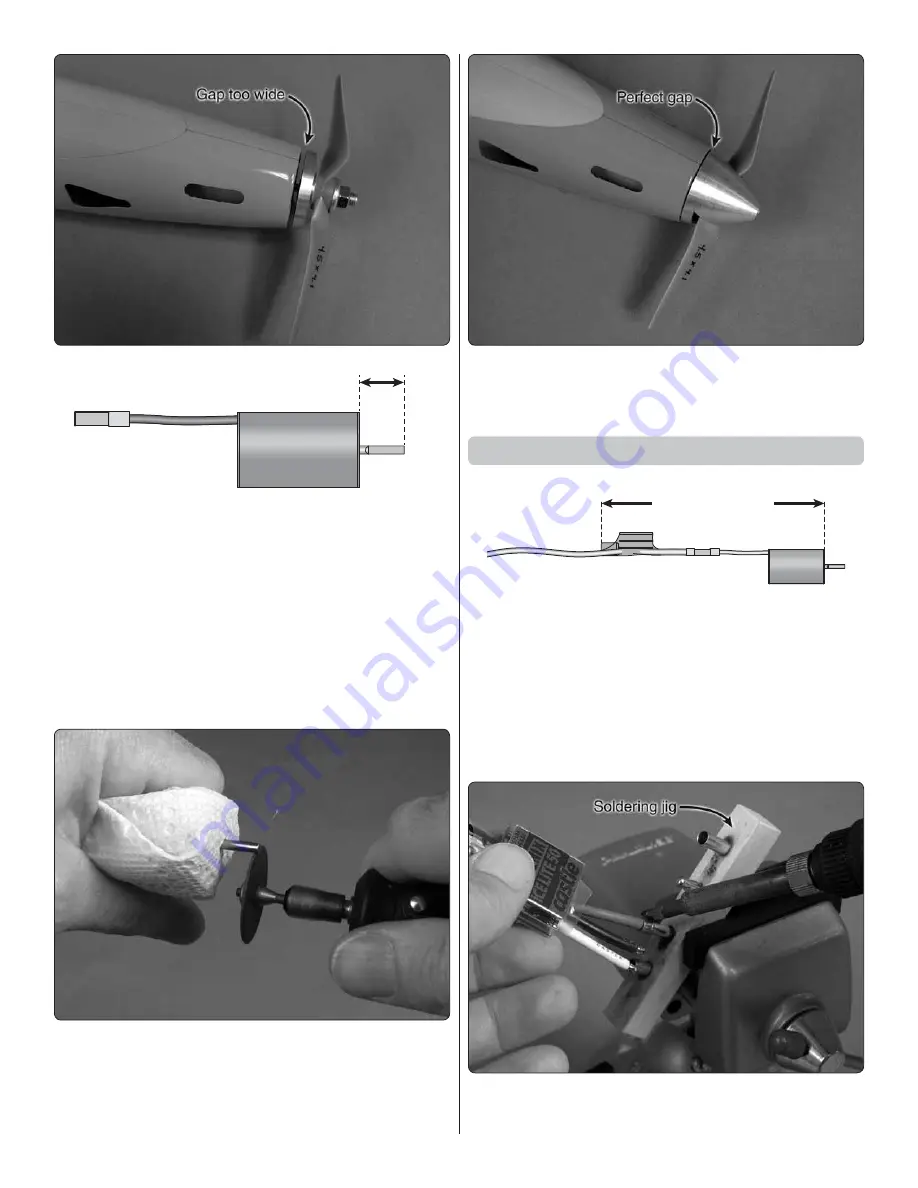

7. Test-mount the propeller and spinner to the motor. It is

likely that the motor shaft will have to be shortened to set the

spinner close enough to the fuselage—it is desirable to have

the shaft as long as possible to give the collet shaft as much

material as possible to “grab” onto, yet still have the desired

spacing between the fuselage and spinner. The proper

spacing is such that the spinner is as close to the fuselage

as possible without touching—a gap just wide enough to see

light through. Typically, a maximum of 13mm—14mm and a

minimum of about 10mm—11mm of motor shaft will work. In

the case of the Ammo motor used here, approximately 2mm

will have to be cut.

❏

8. Remove the motor from the fuselage and cut the

shaft—a Dremel with a reinforced cutoff wheel works best.

Wear safety glasses and protect the motor from metal dust

while cutting.

❏

9. Use a metal fi le or sandpaper to deburr the end of the

shaft. Remount the motor and test-fi t the spinner to see if the

gap is right. Make adjustments if necessary.

Prepare the Motor and ESC

6-1/2" – 7"

[165mm-175mm]

❏

1. As shown in the illustration at step 1 on page 5, the

ESC fi ts best inside the fuselage resting over the battery

ahead of the wing. Usually, this requires cutting the three

motor wires from the ESC just about as short as practically

possible—the distance available between the front of

the motor and the back of the ESC is about 6-1/2" to 7"

[165mm - 175mm]. Determine the length of wires needed

from your ESC (taking into account the length of the bullet

connectors), and then cut the wires to length.

❏

2. If using the recommended Ammo motor, solder the

female bullets that came with the motor onto the motor wires

on the ESC. You can make a handy soldering jig by drilling

Содержание Rifle 1M

Страница 24: ......