13

Connecting non-metallic vent pipe and fittings with thermal insulation shall be prohibited.

Horizontal portions of the venting system shall be supported to prevent sagging by installing

support every 36 inches. The horizontal runs must be sloping upwards not less than ¼ inch per

foot from the boiler to the chimney connector.

A furnace shall not be connected to a chimney flue serving a separate appliance designed to

burn solid fuel.

Provisions for adequate combustion and ventilation air shall be in accordance with one of the

following:

1. Section 5.3, Air for Combustion and Ventilation, of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 ,

2. Sections 7.2, 7.3 or 7.4 of Natural Gas and Propane Installation Code, CSA B149.1 ,

3. Applicable provisions of the local building code.

CONDENSATION

If you have condensation in your chimney, make sure that the

chimney size is according to the tables in THE NATIONAL FUEL

GAS CODE ANDSI Z223.1/NFPA 54 AND/OR NATIONAL GAS AND

PROPANE

INSTALLATION

CODE

CAN/CSA

B149.1.

The

temperature at the entrance of the chimney can be increased by

insulating the flue-pipe between the furnace and the chimney base.

If this is not sufficient, consider cutting or removing some flue

baffles in the furnace.

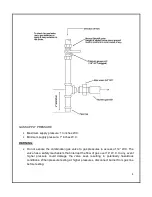

CHIMNEY/VENT Furnace is approved for factory built chimney type “L” vents. Breech is

certified for 5” vent pipe. Keep vent/flue pipe as short as possible with a

minimum upward slope of ¼’’ per foot. Vent/flue pipes MUST NOT pass

through a ceiling. Maximum flue gas temperature is 575°F.

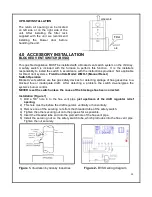

COMBUSTION &

Install openings and ductwork to the furnace room providing fresh

VENTILATION AIR outside combustion and circulation air for cooling the furnace casing, as

installation code requires. If installed in a closed room, provide two free

air ventilation openings of at least 8” x 12” (96 sq. in.) free flow area near

ceiling and floor. Gas burners must have sufficient air to allow vent

systems to operate properly.

DRAFT

Use approved DOUBLE ACTING draft control supplied for 5” pipe. Set

specified draft minimum pressure of -0.01” wc. THE CHIMNEY MUST

BE EQUIPPED WITH A DOUBLE ACTING DRAFT REGULATOR.

FAILURE TO COMPLY WITH THIS MAY RESULT IN IMPROPER

OPERATION LEADING TO POTENTIAL DANGEROUS OPERATION

OF UNIT AND INJURIES TO PERSON AND LOSS OF LIFE.