Grounding

12

311164M

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

1.

Connect the ground wire (244524) (L) to the ground

stud on the air motor.

2.

Connect the other end of the ground wire to a true

earth ground.

3.

Ground the object being sprayed, fluid supply con-

tainer, and all other equipment in the work area. Fol-

low your local code. Use only electrically conductive

air and fluid hoses.

4.

Ground all solvent pails. Use only metal pails, which

are conductive, placed on a grounded surface. Do

not place pail on a nonconductive surface, such as

paper or cardboard, which interrupts grounding con-

tinuity.

Setup

1.

Ground sprayer.

2.

Check packing nut (S). Fill with Throat Seal Liquid

(TSL). Torque to 25-30 ft-lb (34-41 N•m).

3.

Attach electrically conductive fluid hose to pump

outlet and tighten.

4.

Attach electrically conductive fluid hose (and air

hose if using an AA gun) to gun and tighten.

5.

Close bleed type master air valve (B). Connect air

supply hose to 3/4 npt(f) air inlet (A).

6.

Flush before using. See page 14.

7.

Prime before using. See page 14.

Table 1: Tools Required

•

Grounding wires and clamps for pails

•

Two 5 gal. (19 liter) metal pails

F

IG

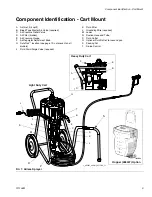

. 3

L

TI8250a

TI1102-2

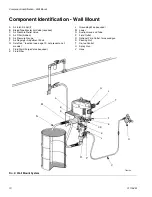

TI1102-1

To avoid tip over, ensure cart is on a flat and level sur-

face. Failure to do so could result in injury or equip-

ment damage.

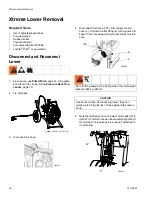

Table 2: Tools Required

•

Two adjustable wrenches

•

Non-sparking hammer or plastic mallet

•

Torque wrench

S

TI8316a

A

B

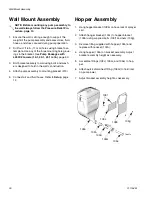

Содержание xtreme

Страница 27: ...Hopper Assembly 311164M 27 ...