8

309711

Troubleshooting

LOW OR FLUCTUATING OUTPUT

TYPE OF PROBLEM

WHAT TO CHECK

If check is OK, go to next check

WHAT TO DO

When check is not OK refer to this column

Motor runs and pump strokes

1. Paint supply.

1. Refill and reprime pump.

2. Intake strainer clogged.

2. Remove and clean, then reinstall.

3. Suction tube or fittings loose.

3. Tighten; use thread sealant or sealing tape

on threads if necessary.

4. To see if intake valve ball and piston ball are

seating properly. See page 19.

4. Remove intake valve and clean. Check

balls and seats for nicks; replace if neces-

sary, page 19. Strain paint before using to

remove particles that could clog pump.

5. Leaking around throat packing nut which may

indicate worn or damaged packings. See

page 19.

5. Replace packings, page 19. Also check

piston valve seat for hardened paint or

nicks and replace if necessary. Tighten

packing nut/wet-cup.

6. Pump rod damage.

6. Repair pump, page 19.

7. Capacitor failure. Visually inspect capacitor

near terminals. Ensure that orange safety re-

lief plug is intact.

7. Replace capacitor.

Motor runs but pump does not

stroke

1. Displacement pump pin (9a) (damaged or

missing), page 19.

1. Replace pump pin if missing. Be sure re-

tainer spring (9b) is fully in groove all

around connecting rod, page 19.

2. Connecting rod assembly (9) for damage,

page 17.

2. Replace connecting rod assembly,

page 17.

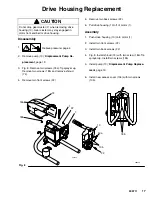

3. Gears or drive housing, page 17.

3. Inspect drive housing assembly and gears

for damage and replace if necessary,

page 17.