Repair

16

3A0411A

Reassembly of Standard Diaphragms

NOTE:

If your pump has overmolded diaphragms, see

page 19.

PTFE Diaphragms

1. Clean all parts and inspect for wear or damage.

Replace parts as needed.

2. Clamp the shaft flats in a vise.

3. For metal pumps, install the washer (18) and o-ring

(17) on the shaft bolt (16).

4. Assemble the fluid side plate (15), the diaphragm

(20), the backup diaphragm (305), the air side dia-

phragm plate (14), and the washer (18) on the bolt

exactly as shown in F

IG

. 6.

5. Apply medium-strength (blue) Loctite or equivalent

to the bolt (16) threads. Assemble into shaft. Torque

the bolt to 110 -120 ft-lb (149-163 N•m) at 100 rpm

maximum.

6. Grease the shaft u-cups (101*) and the length and

ends of the diaphragm shaft (108*). Slide the shaft

into the housing.

7. Repeat Steps 3 and 4 for the other diaphragm

assembly.

8. Apply medium-strength (blue) Loctite or equivalent

to the bolt (16) threads. Screw the bolt into the shaft

hand tight.

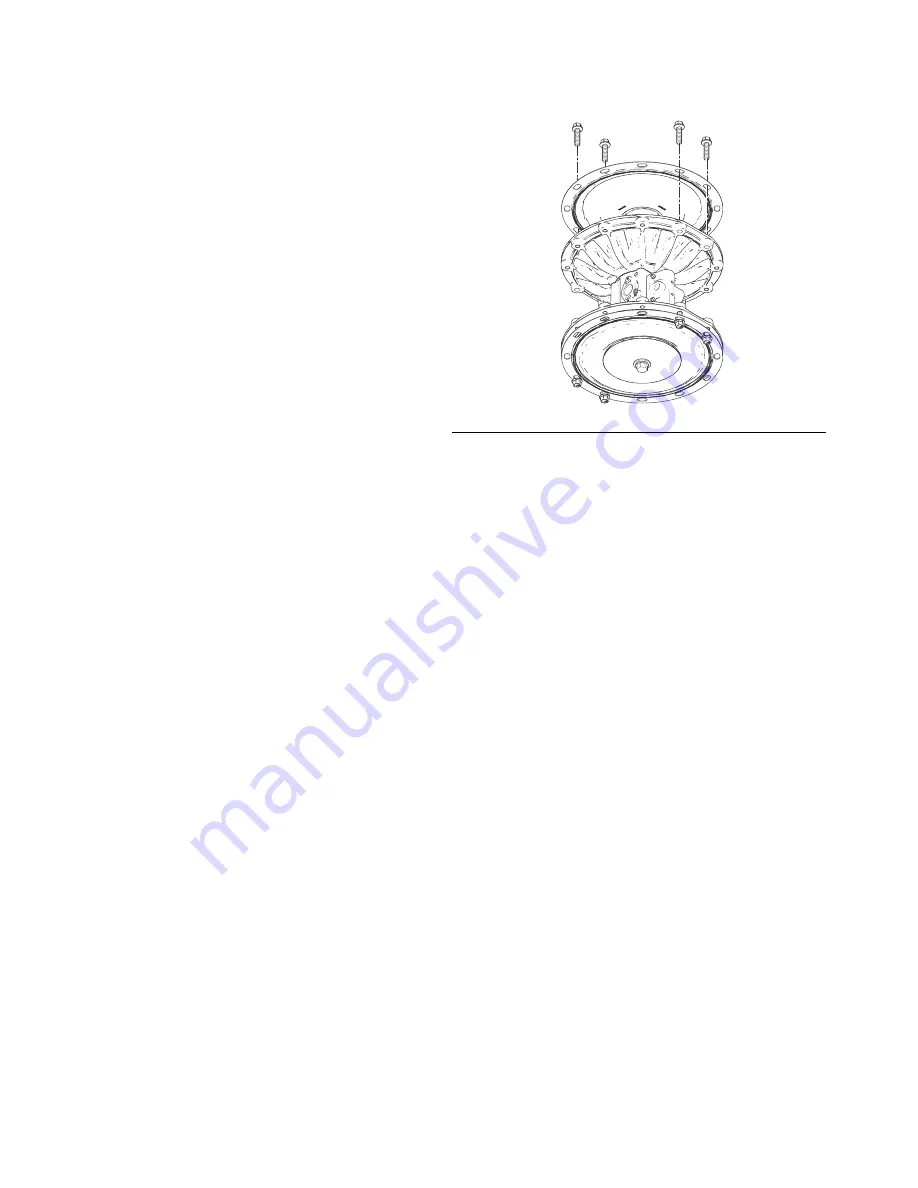

9. To keep the diaphragms properly aligned, place 4

bolts on the side that has been torqued. Screw into

the air cover just enough to engage two threads.

NOTE:

The fluid cover bolts may work well, or use shop

bolts. Do not use bolts that are long enough to deform

the diaphragm manually.

10. Clamp the torqued side in a vise.

11. Again align the diaphragm and air cover holes on

the second side and place 4 more bolts.

12. Torque the shaft bolt on the second side to 110 -120

ft-lb (149-163 N•m) at 100 rpm maximum.

13. Remove the bolts used for alignment.

14. Reattach one fluid cover (2). Arrow (A) must point

page 20.

15. Follow directions under

16. Reassemble the ball check valves and manifolds as

explained on page 12.

F

IG

. 5. Place bolts to keep PTFE diaphragms aligned.

ti18621a