Operation

12

3A5202G

Shutdown

1. Let the hopper run out of dry material.

2. Turn off the water supply while mixer is running to

relieve pressure.

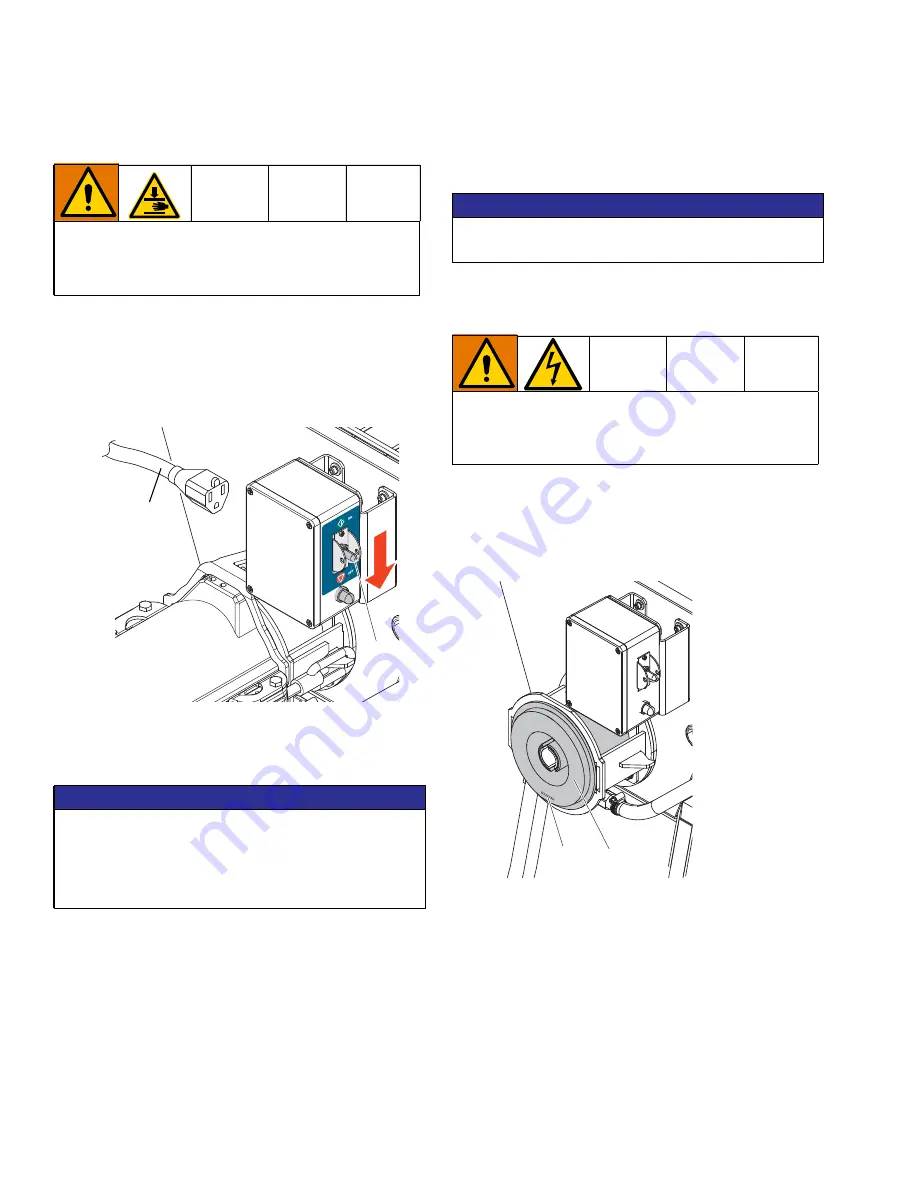

3. Turn the unit off by flipping the switch to the OFF

position.

4. Unplug the power cord (PC) from the mixer.

5. Depressurize/drain water control assembly (D) by

opening water accessory ball valve.

6. Disconnect water supply.

7. Disconnect the motor power cable (CB).

8. Disengage both mix tube toggle latches (FAA) and

remove mix-head assembly (F).

9. Pull the mixing shaft (FB) out of the mixing tube (FA)

and flush both with water and a brush. Make sure all

of the mixing elements on the mixing shaft are

clean.

10. Clean the face of the throat insert (FC).

11. Clean out water dosing port (FCC).

Avoid contact with the discharge nozzle (FF), mix

shaft (FB), and material dosing auger shaft (FD)

during shut down. These parts can pull in, crush, cut,

or amputate fingers and other body parts.

NOTICE

To prevent damage to the water control assembly (D),

drain water from unit if it is to be stored for extended

periods of time or in freezing temperatures. Follow

Changing Material and Storing Equipment

WLD

($

PC

NOTICE

To prevent damage to mix-head assembly, do not

allow material to cure in mix-head assembly.

Do not use pressurized water jets to clean electrical

box, motor, capacitors, or wires. Use of pressurized

water jets can cause water to enter the electrical

controls and increase potential for electric shock.

WLD

)&&

)&

Содержание 25M081

Страница 19: ...Schematics 3A5202G 19 Schematics 25M530 120 Volt Series B 25M530 120 Volt Series A ...

Страница 20: ...Schematics 20 3A5202G 25M563 230 Volt ...

Страница 30: ...Dimensions 30 3A5202G ...