18

307–920

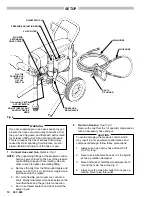

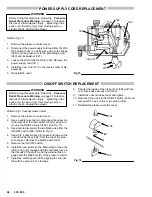

7. Check microswitch (302).Reconnect TP6

connectors.Connect volt meter to TP15

male and TP4. Meter should read 50–125

VAC.

8. Visually inspect microswitch (302) button.

Adjustment stud should not depress the

microswitch button when fluid pressure is

zero. Manually check by depressing but-

ton with small screwdriver; an audible click

indicates microswitch is in normal position.

9. Check microswitch (302) continuity with

ohm meter.

Be sure sprayer is unplugged!

Meter should read zero ohms with no fluid

pressure in the sprayer.

10.Check all terminals for damage or loose fit.

Reconnect TP6 connectors.

11.Check circuit board (23) by substituting

with a good board. See page 29.

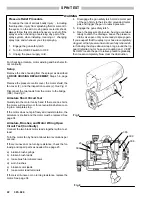

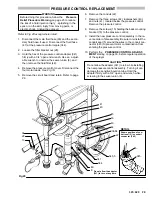

1. Replace circuit board. See page 28.

2. Adjust pressure control to see if that cor-

rects problem. See page 30.

If not, replace pressure control (301)

@

. See

page 29.

MOTOR WON’T OPERATE

Condition B

(continued)

Both lamps off

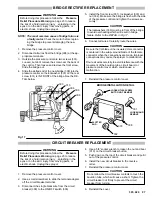

REFER TO THE WIRING

DIAGRAM ON BELOW

TO IDENTIFY T EST

POINTS (TP).

Condition C

Red lamps on,

Clear lamp off

Unplug sprayer!

7. Clean microswitch male terminals. Re-

place loose or damaged terminals. Se-

curely reconnect leads.

8. Microswitch is faulty. Return sprayer for

repair.

9. Microswitch is faulty. Return sprayer for

repair.

10.Replace damaged terminals and recon-

nect securely.

11.Replace circuit board. See page 28.

WHAT TO CHECK

If check is OK, go to the next check.

TYPE OF PROBLEM

WHAT TO DO

If check is not OK, refer to this column.

CIRCUIT

BOARD

OPTICAL

DETECTOR

FLAG

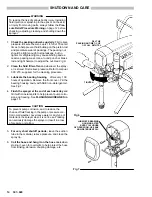

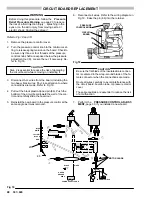

1. Check circuit board (23) by removing from

box

without disconnecting wires; see

page 29 for removal procedure.

WARNING:

Removing the circuit board

while still wired over–rides the optical detec-

tor which could cause the sprayer to over–

pressurize, if the microswitch does not func-

tion properly. Turn the sprayer on

ONLY long

enough to check lamp condition, then shut off

immediately.

WARNING:

To reduce the risk of electric

shock, handle board by edges only! Do not

allow any metal objects to come in contact

with the board!

Plug in and turn on sprayer . Clear lamp

should be on now – removing the circuit

board over–rides the optical detector .

Turn off and unplug the sprayer.

2. Check bourdon tube flag and detector po-

sition. Reinstall circuit board (see page

29). Turn pressure setting to maximum;

flag should extend less than half way into

optical detector slot from the bottom.

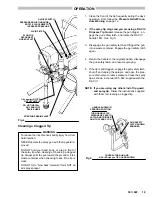

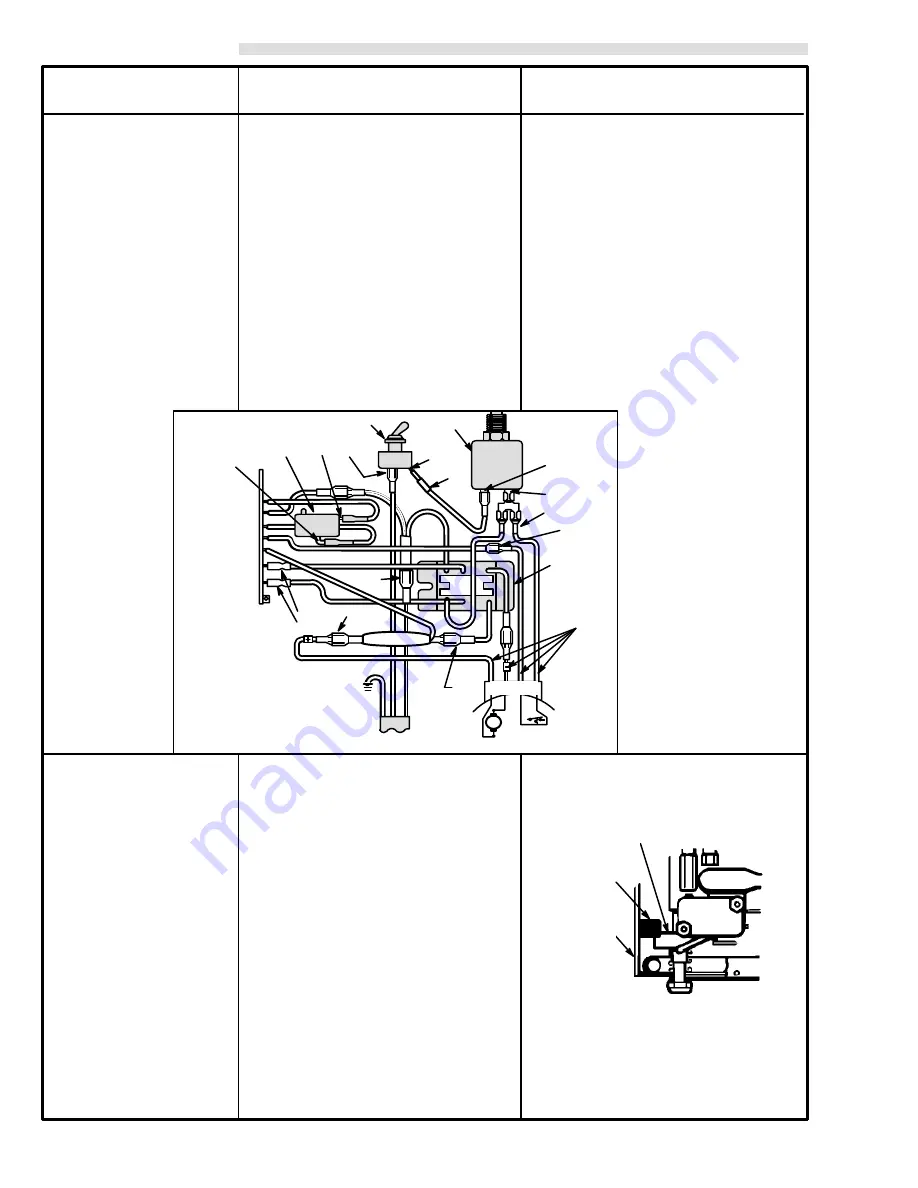

AC1

AC2G2

_

+

G1

WIRING DIAGRAM

306

303

309

308

TP6

TP16

TP10

TP9

TP14

TP13

TP7

TP15

MOTOR

LEADS

NOTE:

These leads have

interchangeable

connections:

TP9

and

TP10

TP13

and

TP14

TP15

and

TP16

WHITE

BLUE

YELLOW

RED

GREEN

BLACK

WHITE

THERMAL SWITCH

GROUND

WIRE

BLACK

POWER SUPPLY CORD

MOTOR

302

TP8

TP1

TP2

TP3

TP4

Содержание 231-081

Страница 47: ...47 307 920...