Operators

manual

Gorter-Controls B.V. – Schoonhoven- The Netherlands

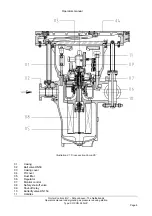

2.4 Operation

Regulator

Gas flows from the gas pipe through the ball valve into the casing. The dust filter prevents dirt particles from

entering the cartridge. Gas flows past the opened shut off valve and monitor control to the regulator. The

required outlet pressure is set by the regulator pilot.

The higher the gas consumption level, the further the regulator will open. If the inlet pressure is increased

then the passage will reduce. The result is a constant outlet pressure, according to the value set on the pilot,

independent of the gas consumption.

First safety device: Monitor control

Should the regulator malfunction, then the monitor control takes over the function of the regulator and

ensures that the gas supply is maintained. The value on the monitor control pilot is set at higher value, than

the value set on the regulator pilot and therefore the gas pressure will be slightly higher.

Second safety device: Shut off valve

Should the monitor control also malfunction, then the shut off valve will cut off the gas supply. The value at

which the relay activates is slightly higher, than the value set on the monitor control pilot.

When the regulator and monitor control malfunctions have been corrected, the shut off relay can be reset by

pressing a button, which causes the shut off valve to open.

Illustration 2.2 'Flow scheme COCON 26'

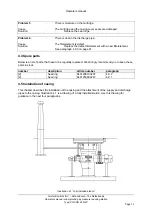

Objectives

The operation of the gas pressure reducing station should meet the following objectives:

-

There may not be any gas leakages.

-

The outlet pressure must be equal to the pressure set on the regulator pilot.

-

No dirt particles in the discharge pipe.

-

No moisture may enter the casing.

Operators manual underground gas pressure reducing station

Type: COCON 26 N-LP

Page 8